مقدمة

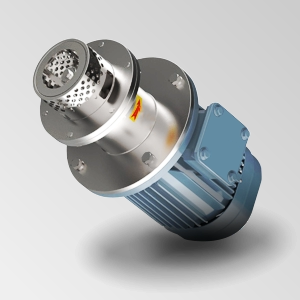

High shear mixers have a wide range of applications across various industries, and one such industry where they play a significant role is the pesticide industry. The efficient mixing capabilities of high shear mixers are instrumental in the production of pesticides, ensuring uniformity, proper dispersion of active ingredients, and enhancing the overall effectiveness of these agricultural products.

Formulation and Mixing

High shear mixers are essential in the formulation and mixing processes of pesticides. They enable thorough blending of different ingredients, such as active chemicals, surfactants, solvents, and additives. The intense shear forces generated by high shear mixers promote rapid and uniform dispersion of the active ingredients, ensuring their effective distribution throughout the pesticide formulation. This uniform dispersion enhances the efficiency of the pesticide, allowing for better coverage and adherence to target plants or pests.

Emulsification and Suspension

Pesticides often require the creation of stable emulsions or suspensions to enhance their application and effectiveness. High shear mixers excel in the emulsification and suspension of oil-based or solid-based active ingredients in water or other carrier fluids. The high-speed rotation and intense shearing action break down larger particles or droplets, resulting in finely dispersed emulsions or suspensions. This enables the active ingredients to remain suspended or emulsified for longer periods, ensuring consistent performance and preventing settling or separation.

تخفيض حجم الجسيمات

In pesticide manufacturing, achieving a specific particle size is crucial for optimal performance. High shear mixers facilitate particle size reduction, ensuring uniformity and enhancing the effectiveness of the pesticide. By subjecting the ingredients to intense shear forces, high shear mixers break down larger particles, resulting in smaller and more consistent particle sizes. This not only improves the dispersibility and stability of the pesticide but also enhances its efficacy in targeting pests or diseases.

Time and Cost Efficiency

High shear mixers offer significant time and cost savings in pesticide production. The rapid and efficient mixing capabilities of these mixers reduce processing times, allowing for increased production rates. The elimination of manual mixing and the ability to handle large batch sizes further contribute to improved productivity. Additionally, high shear mixers require minimal maintenance and offer easy cleaning, reducing downtime and ensuring continuous operation. The overall time and cost efficiencies achieved by using high shear mixers make them indispensable tools in the pesticide industry.

Quality and Consistency

The uniform and consistent mixing achieved with high shear mixers significantly improves the quality and consistency of pesticide formulations. The thorough dispersion and distribution of active ingredients result in consistent efficacy and performance across different batches. This ensures that farmers and growers can rely on the consistent effectiveness of the pesticides, leading to improved crop protection and yields.

خاتمة

High shear mixers have become invaluable in the pesticide industry, enabling efficient formulation, thorough mixing, emulsification, particle size reduction, and ensuring consistent quality. Their role in enhancing pesticide performance, productivity, and overall effectiveness demonstrates their importance in supporting sustainable agriculture practices and crop protection.

SeFluid هي شركة صينية رائدة في تصنيع معدات معالجة السوائل. على مدار العقد الماضي ، تم استخدام منتجاتنا على نطاق واسع في العديد من تطبيقات السوائل في جميع أنحاء العالم. الرجاء النقر فوق المنتجات ذات الصلة أدناه لمعرفة المزيد من التفاصيل أو إرسال استفسار إلينا ، وسيقوم مهندسو المبيعات لدينا بالاتصال بك في أقرب وقت ممكن.

منتجات ذات صله

طلب عرض أسعار

اتصل

No 28, Fengxia Rd, Hefei, Anhui Province, China 201400

Phone: +86 156 6910 1862

Fax: +86 551 5843 6163

power.diulfesobfsctd-122838@selas