Spaltrohrmotorpumpen

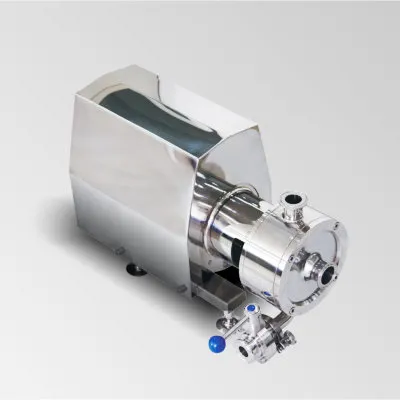

In the ever-evolving field of fluid handling, the introduction of canned motor pumps has marked a significant technological advancement. These pumps, known for their leak-free operation and high efficiency, have become indispensable in various industries. SeFluid, a leading manufacturer in this domain, has been at the forefront of providing top-notch canned motor pumps that cater to diverse industrial needs.

What Are Canned Motor Pumps?

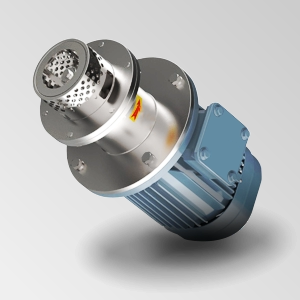

Canned motor pumps are a type of centrifugal pump that integrates the motor and pump into a single, hermetically sealed unit. This design eliminates the need for mechanical seals, which are often the source of leaks and maintenance issues in traditional pumps. The motor is enclosed within a can, which is filled with the pumped fluid. This fluid circulates through the motor, providing cooling and lubrication.

Key Features

- Leak-Free Operation: The hermetically sealed design of canned motor pumps ensures that there are no leaks, making them ideal for handling hazardous or toxic fluids.

- Geringer Wartungsaufwand: With no mechanical seals to wear out, this type of pumps require significantly less maintenance compared to traditional pumps.

- Hohe Effizienz: The integrated design reduces energy losses, resulting in higher efficiency.

- Kompaktes Design: The pumps are typically more compact than traditional pumps, saving valuable space in industrial settings.

- Leiser Betrieb: The enclosed design also helps to reduce noise levels, making these pumps suitable for environments where noise reduction is important.

Spezifikation

TYPE SELECTION OF CANNED MOTOR PUMPS

Anwendungen

Canned motor pumps are a type of industrial pump that have a number of useful applications across various industries. Here are some of the key applications of canned motor pumps:

Chemical and Petrochemical Industry:

- Handling corrosive, toxic, or flammable liquids safely due to the leak-proof design

- Circulating and transferring chemicals, solvents, and other process fluids

- Pumping liquefied gases like LPG and LNG

Power Generation:

- Circulating cooling water in nuclear power plants

- Handling boiler feed water and condensate in thermal power plants

Wasser- und Abwasserbehandlung:

- Pumping clean water, wastewater, and effluents

- Handling sludge and slurries in treatment plants

Oil and Gas Industry:

- Transferring crude oil, refined products, and other hydrocarbon liquids

- Boosting pressure in pipelines

- Pumping drilling muds and other oilfield fluids

Pharmaceutical and Biotech Industries:

- Handling sterile and high-purity liquids without contamination

- Pumping viscous, shear-sensitive, or abrasive fluids

Lebensmittel- und Getränkeverarbeitung:

- Transferring and dosing food-grade liquids like oils, juices, and syrups

- Pumping liquids with suspended solids like fruit pulp or slurries

HVAC-Systeme:

- Circulating chilled water, glycol solutions, and other heat transfer fluids

Marine Applications:

- Bilge water, ballast water, and other shipboard fluid transfer

The key advantages of canned motor pumps that make them suitable for these applications include their leak-proof design, ability to handle harsh and corrosive fluids, high efficiency, and low maintenance requirements.

Why Choose SeFluid’s Canned Motor Pumps?

At SeFluid, we pride ourselves on providing top-quality canned motor pumps that meet the highest standards of safety and efficiency. Our pumps are designed to handle the most demanding applications, offering reliable performance and long service life. Here are some reasons to choose SeFluid:

- Expertise: With years of experience in the industry, we have the knowledge and expertise to provide the best solutions for your fluid handling needs.

- Quality: Our pumps are manufactured to the highest standards, ensuring reliable and leak-free operation.

- Anpassung: We offer customized solutions to meet the specific requirements of your application, ensuring optimal performance.

- Support: Our team of experts is always available to provide support and assistance, ensuring that you get the most out of your pumps.

Advancements in Canned Motor Pump Technology

The technology behind canned motor pumps has evolved significantly over the years. Modern pumps are equipped with advanced features such as variable speed drives, which allow for precise control of pump performance. This not only enhances efficiency but also extends the lifespan of the pump.

SeFluid has been at the forefront of these technological advancements, continuously improving its products to meet the changing needs of the industry. The company’s research and development team is dedicated to exploring new materials and technologies that can further enhance the performance and reliability of canned motor pumps.

Environmental and Safety Benefits

In addition to their operational advantages, canned motor pumps offer significant environmental and safety benefits. The leak-free design minimizes the risk of fluid spills, protecting the environment and ensuring the safety of personnel. Furthermore, the high efficiency of these pumps reduces energy consumption, contributing to lower carbon emissions and a smaller environmental footprint.

SeFluid is committed to sustainability and environmental responsibility. The company’s canned motor pumps are designed with these principles in mind, providing eco-friendly solutions for fluid handling. By choosing SeFluid’s products, industries can achieve their operational goals while minimizing their impact on the environment.

Future Trends and Developments

The future of canned motor pumps looks promising, with ongoing research and development efforts aimed at further improving their performance and capabilities. Innovations in materials science, such as the use of advanced composites and coatings, are expected to enhance the durability and efficiency of these pumps.

SeFluid is poised to lead the way in these developments, leveraging its expertise and experience to bring cutting-edge solutions to the market. The company’s focus on customer satisfaction and continuous improvement ensures that it remains a trusted partner for industries worldwide.

conclusion

Canned motor pumps are a vital tool in ensuring safe and efficient fluid handling in various industries. With their leak-free operation, low maintenance requirements, and high efficiency, these pumps offer numerous advantages over traditional pumps. At SeFluid, we are dedicated to providing the best canned motor pumps on the market, helping our customers achieve their goals with reliable and high-quality products.

Angebotsanfrage

Sprechen Sie jetzt mit uns

Wir empfehlen Ihnen dringend, entweder auf den untenstehenden QR-Code zu klicken oder ihn zu scannen, um direkt mit unseren Vertriebsingenieuren zu sprechen, damit wir Ihnen helfen können, die am besten geeigneten Produkte für Ihre Anwendungsanforderungen zu finden.