Introduction to SeFluid Batch High Shear Mixers

SeFluid has established itself as a reputable brand in the field of industrial mixing solutions, renowned for its innovative and high-performance equipment. Among its diverse range of offerings, the batch high shear mixer stands out for its efficiency and adaptability across various sectors. SeFluid’s batch high shear mixers are specially designed to meet the demanding requirements of industries such as pharmaceuticals, food processing, and chemicals, ensuring optimal mixing and processing outcomes.

High shear mixers, including those from SeFluid, play a crucial role in processes that require the uniform dispersion of materials. These mixers operate by applying intense mechanical energy to break down particles and uniformly distribute them throughout the mixture. The batch high shear mixer, in particular, is designed for applications where precise control over the mixing process is essential, allowing for consistent and repeatable results.

SeFluid offers a range of batch high shear mixers tailored to various industrial needs. These mixers come with different configurations and capacities, making them suitable for both small-scale laboratory applications and large-scale production environments. The versatility of SeFluid’s batch high shear mixers allows them to handle a wide variety of substances, from viscous fluids to fine powders, thereby enhancing productivity and efficiency in manufacturing processes.

The importance of high shear mixers in industries cannot be overstated. In the pharmaceutical industry, they ensure the homogeneous blending of active ingredients, which is critical for the efficacy and safety of medications. In food processing, these mixers help achieve the desired texture and stability of products like sauces, dressings, and dairy items. Similarly, in the chemical industry, batch high shear mixers facilitate the production of emulsions, dispersions, and other complex formulations, ensuring consistency and quality.

SeFluid’s commitment to quality and innovation is evident in their batch high shear mixers, which are designed to deliver superior performance and reliability. By investing in advanced technologies and adhering to stringent manufacturing standards, SeFluid continues to set the benchmark for excellence in industrial mixing solutions.

Key Advantages of SeFluid Batch High Shear Mixers

SeFluid batch high shear mixers offer a multitude of advantages that make them a preferred choice in various industries. One of the primary benefits is their exceptional efficiency. By utilizing high shear forces, these mixers effectively reduce particle sizes, ensuring a uniform and consistent mixture. This capability is particularly beneficial in industries where homogeneity and precision are critical, such as pharmaceuticals, cosmetics, and food processing.

Cost-effectiveness is another significant advantage. SeFluid mixers are designed to optimize resource utilization, thereby minimizing waste and reducing operational costs. The mixers’ high efficiency translates into shorter processing times, which further contributes to cost savings. Additionally, their energy-efficient design ensures that operational costs remain low, making them an economically viable option for businesses of all sizes.

Versatility is a hallmark of SeFluid batch high shear mixers. They are adaptable to a wide range of applications, from emulsifying and homogenizing to dispersing and dissolving. This versatility means that a single mixer can be used for multiple processes, reducing the need for additional equipment and thereby saving on capital expenditure.

Durability and ease of maintenance are also key advantages. SeFluid mixers are constructed from high-quality materials that ensure longevity and robust performance. The design incorporates features that simplify maintenance tasks, such as easy-to-clean surfaces and accessible components, reducing downtime and maintenance costs. Safety features, such as automatic shut-off mechanisms and overload protection, are integrated to ensure operator safety and equipment longevity.

Real-world testimonials underscore the reliability and effectiveness of SeFluid batch high shear mixers. For instance, a leading pharmaceutical company reported a 30% increase in production efficiency after integrating SeFluid mixers into their process. Similarly, a cosmetics manufacturer noted significant improvements in product consistency and quality. These testimonials highlight the practical benefits and positive impact of SeFluid mixers in various industrial applications.

Functions and Applications of SeFluid Batch High Shear Mixers

SeFluid batch high shear mixers are pivotal in numerous industrial processes due to their versatile functionality. At their core, these mixers excel in emulsification, homogenization, particle size reduction, and dispersion. Each function is crucial for producing high-quality, consistent products across various sectors.

Emulsification, a primary function of SeFluid batch high shear mixers, involves the creation of stable mixtures from immiscible liquids, such as oil and water. This is particularly essential in the cosmetics industry, where the production of smooth, uniform creams and lotions depends on effective emulsification. Likewise, in the food and beverage industry, emulsification is key to producing homogeneous sauces and dressings with desirable textures and flavors.

Homogenization, another significant function, ensures uniform distribution of particles throughout a solution, which enhances product stability and consistency. In the pharmaceutical industry, homogenization is vital for creating stable suspensions, where active pharmaceutical ingredients must be evenly distributed to ensure effective dosage and product efficacy. This functionality is also important in the production of dairy products, such as milk and cream, where uniformity is critical for quality control.

Particle size reduction is achieved through the intense mechanical action of SeFluid batch high shear mixers, which breaks down larger particles into finer ones. This is a crucial process in industries requiring smooth, refined products. For instance, in the paint and coatings industry, reducing particle size enhances the final product’s appearance and performance by ensuring a smoother finish and better coverage.

Dispersion, the final key function, involves the even distribution of solid particles within a liquid medium. This is essential in various applications, such as the production of inks, where consistent dispersion ensures uniform color and quality. In the chemical industry, dispersion is necessary for creating stable mixtures and solutions, enhancing product performance and stability.

The versatility of SeFluid batch high shear mixers allows them to be employed across diverse applications, making them indispensable tools in industries ranging from pharmaceuticals and cosmetics to food and beverages, and beyond. Their ability to efficiently perform multiple functions underscores their importance in modern manufacturing processes.

Working Principle of SeFluid Batch High Shear Mixers

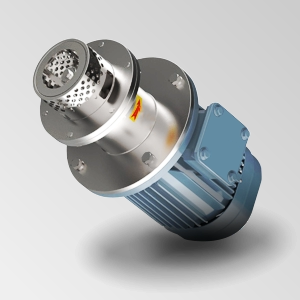

SeFluid batch high shear mixers are designed to facilitate efficient and effective mixing through a sophisticated rotor-stator mechanism. This mechanism lies at the core of the mixer’s ability to apply intense shear forces to materials, ensuring they achieve the desired consistency and homogeneity. The rotor, a rapidly spinning component, works in conjunction with the fixed stator to create a powerful shearing action. This interaction generates high turbulence and shear within the mixing chamber, breaking down and dispersing particles thoroughly.

The mixing process begins as materials are drawn into the mixing head. The rotor’s centrifugal force propels the materials outward towards the stator. As the materials pass through the narrow gap between the rotor and stator, they experience intense mechanical shear. This shearing action is critical for reducing particle size, blending immiscible liquids, and achieving fine emulsions. The high velocity of the rotor ensures that the materials are subjected to repeated shearing cycles, enhancing the mixing efficiency.

SeFluid batch high shear mixers are equipped with adjustable operational parameters to cater to various mixing needs. The rotational speed of the rotor can be varied, allowing control over the shear intensity. This flexibility enables the mixer to handle a broad range of viscosities and material properties. Additionally, the gap between the rotor and stator can be fine-tuned to optimize the shearing action for specific applications. These adjustments ensure that the mixer can be tailored to achieve precise mixing results across different industries.

Visual aids such as diagrams or illustrations can further elucidate the intricate workings of the SeFluid batch high shear mixer. These may depict the flow of materials, the rotor-stator interaction, and the resultant shear forces applied within the mixer. Understanding these elements is crucial for operators to optimize the mixer settings and achieve the desired product quality.