Introduction to SeFluid High Shear Dispersers

A high shear disperser is an advanced piece of equipment designed to mix, emulsify, homogenize, and disperse various substances, creating a uniform and stable mixture. This tool operates on the principle of high-speed rotor-stator configurations that generate intense shear forces. These forces break down and evenly distribute particles within a liquid, resulting in a fine and consistent dispersion. High shear dispersers are indispensable in many industries, including pharmaceuticals, cosmetics, food and beverages, chemicals, and coatings.

SeFluid, a leading manufacturer of high shear dispersers, has carved a niche in the market with its innovative and high-quality products. Established with a vision to provide top-notch mixing solutions, SeFluid combines cutting-edge technology with extensive industry experience. Their high shear dispersers are engineered to meet the rigorous demands of modern production processes, ensuring efficiency, reliability, and superior performance.

The history of SeFluid is a testament to its commitment to excellence and innovation. Over the years, the company has continually evolved, embracing new technologies and refining its products to better serve its customers. This dedication has positioned SeFluid as a trusted name in the industry, known for producing dispersers that enhance productivity and product quality.

SeFluid’s high shear dispersers are designed with versatility in mind, capable of handling a wide range of applications. Whether it’s breaking down solid particles, creating stable emulsions, or achieving fine homogenization, SeFluid’s dispersers deliver consistent results. These machines are not only efficient but also user-friendly, making them a valuable asset in any production setting.

In summary, a high shear disperser is a critical tool across various sectors, and SeFluid stands out for its expertise and high standards in manufacturing these devices. By understanding the fundamental principles and history behind SeFluid’s high shear dispersers, one can appreciate their pivotal role in modern industrial processes.

Key Features and Technical Specifications

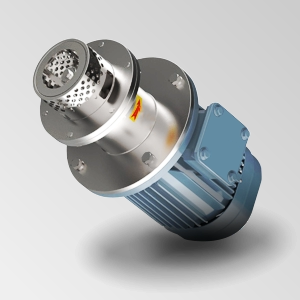

SeFluid’s high shear dispersers are distinguished by their superior design and technical specifications, making them a preferred choice in various industries. One of the standout features of these dispersers is their robust construction. Built using high-quality materials, they are designed to endure rigorous operational demands, ensuring longevity and reliability. The ease of use is another hallmark of SeFluid’s high shear dispersers, with user-friendly interfaces that simplify operation and reduce the learning curve for new users.

Maintenance is a key consideration in the design of these dispersers. SeFluid has incorporated features that facilitate straightforward maintenance, minimizing downtime and ensuring consistent performance. Various models are available, catering to different operational needs. For instance, the power capacities range from 1.5 kW to 75 kW, allowing users to select a model that aligns with their specific requirements. Additionally, the operational speeds vary between 1,000 to 30,000 RPM, providing versatility in handling different materials and processes.

Customization is another area where SeFluid excels. Clients can opt for bespoke solutions tailored to their unique needs, including adjustable speed controls and interchangeable rotor-stator configurations. This flexibility ensures that the high shear dispersers can be fine-tuned to achieve optimal results across a broad spectrum of applications.

SeFluid’s high shear dispersers also incorporate several unique technologies that enhance performance and efficiency. For example, some models feature patented dispersion heads that significantly improve mixing quality and reduce processing time. These innovations not only boost efficiency but also ensure homogeneous dispersion of materials, which is critical in industries such as pharmaceuticals, cosmetics, and food processing.

In summary, the combination of robust construction, ease of use, customizable options, and cutting-edge technology positions SeFluid’s high shear dispersers as a leading choice for businesses seeking reliable and efficient mixing solutions.

Applications and Industry Uses

SeFluid high shear dispersers are pivotal in various industries due to their efficiency and versatility in processing applications. In the pharmaceutical sector, these dispersers play a crucial role in the production of medications, where precise emulsification and homogenization are essential. For instance, the creation of stable emulsions for injectable drugs and the uniform distribution of active pharmaceutical ingredients (APIs) in liquid formulations rely heavily on high shear dispersers. A notable case involves a leading pharmaceutical company that reported a 30% increase in production efficiency after integrating SeFluid dispersers into their manufacturing line.

The food and beverage industry also greatly benefits from SeFluid high shear dispersers. These devices are used to achieve consistent textures and flavors in products such as sauces, dressings, and beverages. High shear dispersers are instrumental in reducing particle sizes and creating stable emulsions, which are crucial for the mouthfeel and stability of food products. A prominent food manufacturer noted significant improvements in product quality and consistency, attributing these advancements to the integration of SeFluid technology in their processing systems.

In the cosmetics industry, the importance of high shear dispersers cannot be overstated. These devices are vital in producing creams, lotions, and other personal care products, where uniform particle size and stable emulsions are critical for product performance and consumer satisfaction. SeFluid dispersers enable the efficient mixing of ingredients, ensuring that cosmetic formulations are smooth and free from lumps. A cosmetic company reported enhanced product stability and customer satisfaction after adopting SeFluid high shear dispersers, highlighting the significant impact on their production processes.

The chemical industry also leverages the capabilities of SeFluid high shear dispersers for applications such as polymer dispersions, pigment processing, and the production of specialty chemicals. These dispersers facilitate the uniform mixing and particle size reduction necessary for high-quality chemical products. A chemical manufacturer experienced a notable reduction in production time and improvement in product uniformity, demonstrating the effectiveness of SeFluid high shear dispersers in demanding industrial applications.

Advantages of Choosing SeFluid High Shear Dispersers

When selecting a high shear disperser for your operational needs, SeFluid stands out as a premier choice. One of the foremost advantages of SeFluid high shear dispersers is the significant improvement in product quality. By utilizing advanced technology and precision engineering, these dispersers ensure uniform particle size distribution, resulting in a consistently high-quality end product.

Operational efficiency is another critical advantage. SeFluid high shear dispersers are designed to maximize throughput while minimizing energy consumption. This not only enhances productivity but also reduces operational costs. The robust construction and ease of maintenance further contribute to prolonged equipment life and reduced downtime, ensuring a seamless and efficient production process.

Cost-effectiveness is a hallmark of SeFluid’s offerings. The initial investment in a SeFluid high shear disperser is quickly offset by the savings garnered from reduced energy consumption, lower maintenance costs, and increased production efficiency. Additionally, these dispersers are engineered to deliver versatile performance across various applications, reducing the need for multiple pieces of equipment and, consequently, further lowering capital expenditures.

SeFluid’s commitment to superior customer support distinguishes it from its competitors. From the initial consultation to post-installation services, SeFluid provides comprehensive support to ensure that clients achieve optimal performance from their high shear dispersers. The company’s dedication to customer satisfaction is evidenced by numerous certifications, awards, and industry recognitions, underscoring its reputation for quality and reliability.

To capitalize on these advantages and propel your operations to new heights, we encourage you to contact SeFluid for more information or to request a quote. Discover how SeFluid high shear dispersers can revolutionize your production processes and deliver unparalleled results.