High shear mixers are essential tools in various industries, including pharmaceuticals, cosmetics, and food processing. These versatile machines are specifically designed to handle tasks that require the rapid mixing of materials to produce homogeneous mixtures. In this blog post, we will delve into the high shear mixer working principle, particularly for the high shear mixers manufactured by our company, SeFluid.

The Basic Working Principle

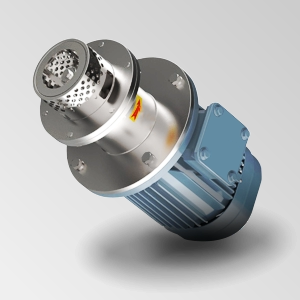

The primary working principle of a high shear mixer revolves around the concept of shear force. The mixer consists of a rotor that spins at high speed within a stationary stator. When the rotor operates, it generates intense shear forces that reduce particle size and disperse materials evenly. This process ensures that even the most challenging ingredients are mixed thoroughly to achieve a consistent product.

Componentes clave y sus funciones

Understanding the components of a high shear mixer is crucial for grasping its working principle. The rotor-stator configuration is at the heart of the mixer. The rotor is a rapidly rotating component that creates centrifugal force, while the stator remains stationary, providing a shearing action. Additionally, the mixer might include a mixing chamber where materials are introduced. The rotor’s high speed causes the materials to move through the stator, undergoing intense shear and turbulence, leading to a uniform mixture.

Applications and Benefits

High shear mixers from SeFluid are used across various industries due to their efficiency and reliability. They are particularly beneficial in applications requiring emulsification, homogenization, and particle size reduction. The high shear forces ensure that ingredients are mixed at a microscopic level, resulting in products of superior quality and consistency. Moreover, these mixers are designed for easy cleaning and maintenance, making them a practical choice for industrial applications.

Conclusión

In summary, understanding the high shear mixer working principle is essential for anyone involved in industries that require precise and efficient mixing. The high shear mixers manufactured by SeFluid are engineered to meet the highest standards, ensuring optimal performance and consistent results. By leveraging the power of shear force, these mixers provide unparalleled mixing capabilities, making them indispensable tools in various production processes.