Introduction to Rotor-Stator Mixers

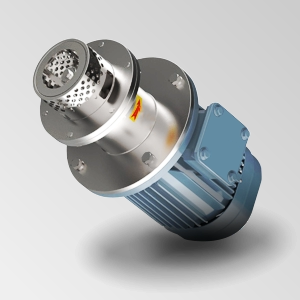

Rotor-stator mixers are advanced mixing devices designed to achieve high-shear mixing, a process essential in various industries. These mixers feature two primary components: the rotor and the stator. The rotor, typically a rapidly spinning blade, works in conjunction with the stationary stator to create intense mechanical shear forces. When materials pass through the narrow gap between the rotor and stator, they are subjected to extreme shear, resulting in finely dispersed particles and homogenized mixtures.

The fundamental principle of rotor-stator mixers lies in their ability to generate high shear rates, which are crucial for breaking down particles and ensuring uniform distribution of ingredients. The rotor’s rapid rotation creates a suction effect, drawing materials into the mixing chamber. As these materials flow through the rotor-stator assembly, they undergo vigorous shearing and turbulence, leading to efficient mixing, emulsification, and dispersion.

Rotor-stator mixers are highly versatile and are employed across a wide range of industries. In the food processing sector, they are used to produce smooth sauces, dressings, and emulsions. The pharmaceutical industry relies on these mixers to achieve consistent particle size reduction and homogenous blends in drug formulations. In the chemical industry, rotor-stator mixers are essential for creating stable emulsions, suspensions, and dispersions, making them invaluable in the production of paints, adhesives, and cosmetics.

Overall, the rotor-stator mixer stands out for its efficiency and ability to handle challenging mixing tasks. Its application extends to any process requiring precise control over particle size and consistency. By leveraging the high-shear capabilities of rotor-stator mixers, industries can achieve superior product quality and enhanced process efficiency, making them a cornerstone of modern mixing technology.

Key Features and Advantages of SeFluid’s Rotor-Stator Mixer

SeFluid’s rotor-stator mixer stands out in the market due to its state-of-the-art design and superior engineering. One of the foremost features is its innovative rotor-stator assembly, which is meticulously crafted to ensure maximum shear and efficient mixing. This advanced design allows the mixer to handle a wide range of viscosities and material properties, making it highly versatile across different industrial applications.

The quality of materials used in SeFluid’s rotor-stator mixer is another significant advantage. Constructed from high-grade stainless steel, the mixer offers remarkable durability and resistance to corrosion, ensuring a longer service life even in harsh processing environments. The precision engineering involved in its construction guarantees consistent performance, reducing the likelihood of mechanical failures and maintenance requirements.

In terms of operational efficiency, SeFluid’s rotor-stator mixer excels by significantly reducing processing times. Thanks to its high-speed rotor and precisely engineered stator, the mixer achieves rapid homogenization, emulsification, and particle size reduction. This efficiency not only speeds up production cycles but also enhances overall productivity, making it a cost-effective solution for businesses.

Product consistency is another critical benefit that SeFluid’s rotor-stator mixer delivers. The high shear forces generated by the rotor-stator interaction ensure uniform distribution of components, resulting in a homogeneous end product. This consistency is vital for industries such as pharmaceuticals, food and beverage, and cosmetics, where product quality and uniformity are paramount.

SeFluid’s commitment to excellence is further validated by numerous case studies and customer testimonials. For instance, a leading pharmaceutical company reported a 30% increase in production efficiency after integrating SeFluid’s rotor-stator mixer into their manufacturing process. Another example from the food processing sector highlighted how the mixer improved the texture and stability of their products, leading to higher customer satisfaction.

In summary, SeFluid’s rotor-stator mixer offers a blend of innovative design, high-quality materials, and precision engineering, making it a standout choice for industries seeking enhanced mixing performance. Its benefits of increased efficiency, reduced processing time, and improved product consistency are well-documented, providing compelling reasons for its adoption in various applications.

Applications and Industry Uses

SeFluid’s advanced rotor-stator mixer is renowned for its versatility and effectiveness across a wide array of industries. In the cosmetics sector, manufacturers utilize this mixer to achieve homogenous emulsions essential for products like lotions, creams, and makeup. The high shear forces generated by the rotor-stator mechanism ensure that even the smallest particles are uniformly dispersed, addressing the challenge of achieving consistency in texture and appearance. This results in high-quality cosmetic products with improved stability and shelf life.

In the food and beverage industry, the rotor-stator mixer plays a critical role in producing emulsions, suspensions, and pastes. For instance, in the production of sauces, dressings, and dairy products, the mixer ensures that ingredients are thoroughly blended, resulting in smooth, consistent textures that meet consumer expectations. The ability to mix ingredients quickly and efficiently reduces processing times and enhances overall production efficiency, making it an invaluable tool in food manufacturing.

The pharmaceutical industry also benefits significantly from SeFluid’s rotor-stator mixer. In the formulation of liquid medications, creams, and ointments, the mixer ensures that active ingredients are evenly distributed throughout the product. This uniformity is crucial for the efficacy and reliability of pharmaceutical products. Moreover, the mixer’s precision can handle sensitive ingredients without degrading them, maintaining the integrity and potency of the final product.

The chemical industry leverages the rotor-stator mixer for processes that require fine dispersion and emulsification of components. In the production of paints, adhesives, and sealants, the mixer’s high shear capabilities ensure that pigments and other additives are thoroughly integrated, resulting in products with superior performance characteristics. The mixer’s efficiency in handling high-viscosity materials and its ability to operate under various conditions make it an essential piece of equipment in chemical manufacturing.

Overall, SeFluid’s rotor-stator mixer showcases its adaptability and effectiveness across multiple industries, addressing unique challenges and delivering consistent, high-quality results. This versatility underscores its reputation as a revolutionary tool in modern mixing technology.

Maintenance and Support: Ensuring Longevity and Efficiency

The longevity and efficiency of the SeFluid rotor-stator mixer are significantly influenced by the adherence to proper maintenance protocols and the availability of comprehensive support services. Routine maintenance is paramount to maximizing the operational lifespan of the mixer. Regular inspection of the rotor and stator components for wear and tear is essential. Any signs of degradation should prompt immediate replacement to prevent operational inefficiencies or potential breakdowns. Lubrication of moving parts and ensuring the seals are intact can also enhance performance and prevent unexpected failures.

SeFluid emphasizes the importance of preventative maintenance, providing detailed guidelines and schedules tailored to the rotor-stator mixer’s specific requirements. Troubleshooting tips are also made available to address common issues that may arise during operation. For instance, if the mixer exhibits unusual vibrations or noises, it is advised to check for misalignment or debris within the mixing chamber. Such proactive measures can mitigate minor issues before they escalate into major problems.

In addition to maintenance practices, SeFluid ensures that spare parts are readily accessible to minimize downtime. The availability of high-quality, genuine spare parts guarantees that the mixer remains in optimal condition throughout its service life. The company maintains a robust inventory, ensuring that critical components are always in stock and can be dispatched promptly.

Customer support services are a cornerstone of SeFluid’s commitment to excellence. Technical assistance is readily available, with experts on hand to provide solutions to complex operational challenges. Furthermore, SeFluid offers comprehensive training programs designed to equip users with the knowledge and skills necessary to operate and maintain the rotor-stator mixer effectively. These programs cover a broad spectrum of topics, from basic operational principles to advanced troubleshooting techniques.

After-sales support is another critical aspect of SeFluid’s service offering. The company provides ongoing support to ensure that customers derive maximum value from their investment. This includes periodic follow-ups, performance assessments, and updates on the latest advancements in mixing technology.

Overall, the robust maintenance and support infrastructure provided by SeFluid underscores the reliability and ease of maintaining the rotor-stator mixer, reassuring potential buyers of the product’s long-term viability and efficiency.