Introduction to High Shear Blenders

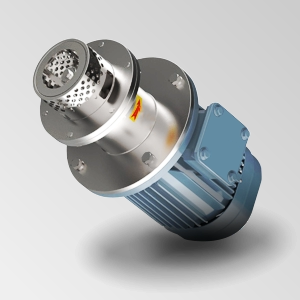

High shear blenders are advanced mixing devices designed to efficiently blend, emulsify, homogenize, or disperse a wide range of substances. These machines operate on the principle of high shear mixing, where intense mechanical energy is applied to break down particles and agglomerates, creating a uniform mixture. The fundamental mechanism involves a rotor-stator assembly that rapidly spins, generating high velocity and shear forces within the blending chamber.

The primary function of a high shear blender is to achieve consistent and stable mixtures, which is crucial in various industrial processes. These blenders are particularly effective in handling both liquids and semi-solids, making them versatile tools in diverse applications. For instance, in the pharmaceutical industry, high shear blenders are used to create smooth, homogenous suspensions and emulsions essential for producing medications. The cosmetics industry relies on these blenders to mix creams, lotions, and gels to achieve the desired texture and stability. In the food and beverage sector, high shear blenders are instrumental in producing sauces, dressings, and beverages, ensuring a consistent product quality. Additionally, in the chemical industry, these blenders are utilized for mixing polymers, resins, and various chemical compounds.

The importance of high shear blenders cannot be overstated, as they offer significant advantages over traditional mixing methods. The ability to achieve rapid and thorough mixing reduces production times and enhances efficiency. Moreover, high shear blenders ensure that the final product meets stringent quality standards, which is vital in industries where product consistency and reliability are paramount.

Understanding the basic operation and applications of high shear blenders is essential for professionals in these industries. By leveraging the capabilities of high shear blenders, companies can improve their product formulations, streamline production processes, and maintain a competitive edge in their respective markets.

Features and Benefits of SeFluid’s High Shear Blender

SeFluid’s high shear blender stands out in the market due to its advanced technical specifications and numerous benefits that cater to diverse industrial mixing needs. At the heart of its functionality is a powerful motor that operates at various speeds, offering flexibility and precision in blending. The motor power ranges from 2 kW to 75 kW, accommodating both small-scale and large-scale production requirements. This versatility ensures that users can select the appropriate power level for their specific applications, optimizing both efficiency and performance.

One of the key features of SeFluid’s high shear blender is its innovative blade design. The blades are engineered to create a high-velocity mixing action, which is crucial for achieving a homogeneous mixture, regardless of the viscosity of the materials being processed. This design allows the blender to handle a wide range of viscosities, making it suitable for various industries, including pharmaceuticals, cosmetics, food and beverage, and chemicals. Moreover, the blade configuration ensures minimal dead space, reducing the risk of material buildup and improving overall hygiene.

The blender also boasts multiple speed settings, which enable precise control over the mixing process. This feature is particularly beneficial for applications that require delicate handling of ingredients to maintain their integrity. By adjusting the speed, users can achieve the desired consistency and texture of the final product, enhancing its quality and marketability.

SeFluid’s high shear blender offers significant advantages that translate into tangible benefits for users. The efficiency of the blender reduces processing times, allowing for faster production cycles and increased throughput. This efficiency also contributes to lower operational costs, as less energy and resources are required to achieve the same results compared to traditional mixing equipment. Additionally, the precision and consistency provided by the high shear blender lead to improved product quality, which is critical in maintaining customer satisfaction and brand reputation.

Real-world examples further underscore the effectiveness of SeFluid’s high shear blender. For instance, a leading cosmetics manufacturer reported a 20% reduction in processing time and a 15% increase in product consistency after integrating the blender into their production line. Another satisfied customer from the food industry highlighted the blender’s capability to handle various viscosities, resulting in a smoother and more uniform final product.

Applications and Use Cases

The SeFluid high shear blender is a versatile tool that finds applications across numerous industries due to its ability to produce high-quality emulsions, dispersions, and suspensions. This adaptability is largely attributed to its specialized design, which ensures efficient and consistent blending, making it indispensable in fields such as pharmaceuticals, food production, cosmetics, and chemicals.

In the pharmaceutical industry, the high shear blender plays a crucial role in the creation of stable emulsions used in topical medications. These emulsions are critical for ensuring that active ingredients are evenly distributed, enhancing the efficacy and stability of the final product. Additionally, the blender is employed in the production of dispersions for oral suspensions, ensuring that the active pharmaceutical ingredients are uniformly distributed, which is essential for accurate dosing.

The food industry also benefits significantly from the capabilities of the high shear blender. It is instrumental in producing smooth and homogenous products such as sauces, dressings, and dairy emulsions. The high shear blender’s ability to break down particles to a fine consistency ensures a superior texture and mouthfeel in the final product. Moreover, it aids in the creation of stable emulsions, crucial for products like mayonnaise and salad dressings, where consistency and stability are key quality factors.

In the cosmetics industry, the high shear blender is used to manufacture creams, lotions, and other personal care products. Its ability to mix ingredients thoroughly ensures that the final products have a consistent texture and efficacy. This is particularly important for products that require the uniform distribution of active ingredients, such as anti-aging creams or sunscreens.

The chemical industry utilizes the high shear blender for creating dispersions and suspensions in products like paints, coatings, and adhesives. The blender’s ability to achieve a fine and uniform particle size distribution is essential for the performance and stability of these products. Additionally, specialized attachments and accessories, such as homogenizing heads and rotor-stator configurations, enhance the blender’s versatility, allowing it to handle a wide range of viscosities and materials.

Real-world scenarios demonstrate that using the SeFluid high shear blender can lead to significant improvements in product quality, consistency, and production efficiency. For instance, a cosmetics manufacturer reported a 30% reduction in processing time and a marked improvement in product texture after integrating the high shear blender into their production line. Such examples underscore the transformative impact of this advanced blending technology across various sectors.

Maintenance and Operational Tips

Ensuring the longevity and optimal performance of your SeFluid high shear blender involves adhering to a consistent maintenance routine. Begin by implementing a daily cleaning schedule. After each use, thoroughly clean the blender to prevent residue build-up, which could affect the efficiency and hygiene of the equipment. Use appropriate cleaning agents that are recommended for stainless steel surfaces and avoid abrasive chemicals that could damage the blender.

Regular inspection is crucial. Check for any signs of wear and tear, such as cracks or corrosion, especially on the blades and seals. Replace any worn parts promptly to avoid compromising the blender’s performance. Lubricate moving parts as specified in the user manual to reduce friction and prevent premature wear.

Troubleshooting common issues is another key aspect of maintenance. If the blender exhibits unusual noises, vibrations, or reduced blending efficiency, check for potential blockages or misalignments in the assembly. Ensure that all parts are securely fastened and operating within the specified parameters. If the issue persists, consult the SeFluid customer support team for guidance.

Safe operation practices are vital for both the longevity of the blender and the safety of the operator. Always load materials according to the recommended capacity to avoid overloading the machine. Set appropriate blending speeds based on the viscosity and nature of the materials being processed. Gradually increase the speed to achieve the desired consistency, rather than starting at high speeds, to prevent motor strain.

Handling the high shear blender with care is also important. Follow the manufacturer’s guidelines for disassembling and reassembling parts to prevent damage. Store the blender in a clean, dry environment when not in use to protect it from moisture and contaminants.

SeFluid offers comprehensive customer support and warranty services to assist users with any technical problems. Take advantage of these resources whenever needed. Register your high shear blender with SeFluid to ensure you receive timely updates and support services. By following these maintenance and operational tips, you can keep your SeFluid high shear blender running smoothly and efficiently for years to come.