Introduction

High shear mixers are indispensable tools in the food industry, offering efficient and precise mixing capabilities. They play a vital role in various food processing operations, ensuring consistent product quality, improving texture, and enhancing overall efficiency. In this article, we will explore the wide-ranging applications of high shear mixers in the food industry.

Emulsification and Homogenization

High shear mixers are widely used in the food industry for emulsification and homogenization processes. These mixers have the ability to break down and disperse immiscible ingredients, such as oil and water, into a stable emulsion. This is crucial in the production of salad dressings, sauces, mayonnaise, and various dairy products. High shear mixers efficiently reduce the particle size, creating a uniform and smooth texture, and preventing phase separation. They can also be utilized for homogenizing milk, improving its consistency and preventing cream separation.

Powder Incorporation and Dissolution

In food manufacturing, it is often necessary to incorporate dry powders into liquids, such as sugar, spices, stabilizers, or nutritional additives. High shear mixers are effective in dispersing and dissolving powders rapidly and uniformly. The high-speed rotation and intense shear forces generated by these mixers create a powerful vortex, ensuring the complete dissolution of the powders and preventing agglomeration. This application is commonly seen in the production of beverages, instant drinks, soups, and sauces, where consistent dispersion and dissolution of powdered ingredients are vital for product quality.

Particle Size Reduction

High shear mixers are utilized for particle size reduction in food processing. They can effectively break down solid particles into smaller sizes, resulting in improved texture, increased surface area, and enhanced flavor release. This application is especially important in the production of sauces, dressings, purees, and baby foods, where a smooth and consistent texture is desired. By reducing the particle size, high shear mixers contribute to the overall sensory experience of the food product.

Mixing and Blending

High shear mixers excel in mixing and blending operations, ensuring consistent distribution of ingredients and uniformity of the final product. They facilitate the combination of multiple components, such as fats, powders, liquids, and flavorings, to create homogeneous mixtures. High shear mixers can be used in the production of baked goods, confectionery, dairy products, and prepared foods, where thorough mixing and blending are crucial for product quality and consistency.

Temperature Control and Cooking

Some high shear mixers are designed to provide precise temperature control and even cooking capabilities. These mixers are equipped with heating or cooling elements, allowing for the preparation of heat-sensitive products. The combination of intense mixing action and controlled temperature ensures efficient heat transfer and uniform cooking. This application is particularly relevant in the production of sauces, confectionery fillings, jams, and syrups, where precise temperature control is essential for achieving desired product properties.

Conclusion

High shear mixers are versatile and indispensable tools in the food industry. They offer numerous benefits, including emulsification, homogenization, powder incorporation, particle size reduction, mixing, blending, and temperature control. By incorporating high shear mixers into food processing operations, manufacturers can achieve consistent product quality, improve texture, enhance flavor release, and optimize efficiency.

RELATED NEWS

Peristaltic Pump Replacement Hoses

Hose for Peristaltic Pump

Tube Pump

Squeeze Pump

Peristaltic Pump

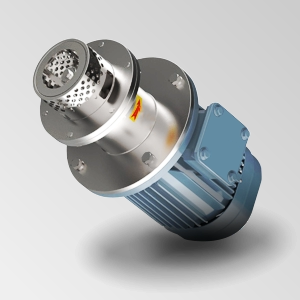

High Shear Mixer Design

SeFluid is a leading China manufacturer of fluid processing equipment. Over the past decade, our products have been widely used in numerous fluid applications worldwide. Please click on below relevant products to learn more details or send us an inquiry, and our sales engineers will contact you as soon as possible.

Request for Quotation

CONTACT

No 10, Jinhai Rd, Hefei, China 201400

Phone: +86 156 6910 1862

Fax: +86 551 5843 6163

moc.diulfesobfsctd-458146@selas