High shear mixers are essential equipment in various industries, known for their ability to blend, emulsify, homogenize, and disintegrate materials with remarkable efficiency. These mixers operate by creating a high-velocity impact between the mixing components, resulting in a uniform and fine particle size distribution. The core principle of high shear mixer design revolves around generating intense shear forces that effectively break down particles and ensure thorough mixing.

The importance of high shear mixers spans across multiple sectors. In the food processing industry, these mixers are indispensable for creating stable emulsions, such as mayonnaise and salad dressings, where consistent texture and flavor are crucial. Pharmaceuticals rely on high shear mixers for the homogenization of active ingredients, ensuring uniformity and efficacy in final products. Similarly, in the cosmetics industry, these mixers facilitate the production of smooth and homogeneous creams, lotions, and makeup formulations.

A primary function of high shear mixers is to achieve fine particle size reduction, which is vital for the stability and quality of the end product. By reducing particle size, high shear mixers enhance the solubility, bioavailability, and overall performance of various formulations. Additionally, these mixers play a critical role in minimizing batch-to-batch variations, leading to consistent product quality and improved process efficiency.

Common applications of high shear mixers include the preparation of emulsions, suspensions, and dispersions. They are also used in the production of paints, adhesives, and chemical intermediates. The versatility of high shear mixer design allows for customization to meet specific process requirements, making them a valuable asset in both small-scale laboratory settings and large-scale industrial operations.

In summary, high shear mixers are pivotal in achieving fine particle size reduction and thorough mixing of components, thereby ensuring the quality and consistency of a wide range of products across different industries. Their ability to handle diverse applications makes them indispensable in modern manufacturing and processing environments.

Key Features of SeFluid’s High Shear Mixer Design

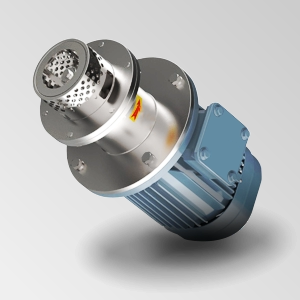

SeFluid’s high shear mixer design is renowned for its innovative and superior engineering, setting it apart from competitors in the industry. One of the standout features is the advanced rotor-stator configuration, which is meticulously designed to enhance mixing efficiency. The rotor-stator mechanism ensures that materials are subjected to intense shear forces, resulting in thorough blending and homogenization. This design feature not only improves process efficiency but also enhances product quality by achieving a consistent and uniform mixture.

The inclusion of variable speed control further distinguishes SeFluid’s high shear mixers. This feature allows operators to adjust the mixing speed according to the specific requirements of different materials and processes. The ability to fine-tune the speed ensures optimal performance, whether dealing with viscous liquids or fine powders. This adaptability significantly boosts the versatility of SeFluid’s mixers, making them suitable for a wide range of applications across various industries.

Durability and longevity are also key considerations in SeFluid’s high shear mixer design. The use of high-quality materials, such as stainless steel and corrosion-resistant alloys, ensures that the mixers can withstand the rigors of continuous operation in demanding environments. This robust construction minimizes maintenance needs and extends the operational lifespan of the equipment, providing cost savings and reliable performance over time.

Ease of maintenance is another critical aspect of SeFluid’s design philosophy. The mixers are engineered with user-friendly features that facilitate quick and straightforward servicing. Components are designed for easy disassembly and cleaning, reducing downtime and ensuring that the mixers can be kept in optimal working condition with minimal effort.

Additionally, SeFluid incorporates patented technologies that further enhance the performance of their high shear mixers. Unique design aspects, such as specialized impeller geometries and precision-engineered flow channels, contribute to superior mixing results. These innovations reflect SeFluid’s commitment to continuous improvement and excellence in high shear mixer design.

Benefits and Applications of SeFluid’s High Shear Mixers

SeFluid’s high shear mixer design offers numerous practical benefits that significantly enhance production processes across various industries. One of the most notable advantages is the increased production efficiency. By leveraging advanced mixing technology, these mixers ensure rapid and thorough blending of materials, reducing the overall processing time. This efficiency translates directly into higher throughput and optimized operational workflows.

Another critical benefit is the consistent product quality achieved with SeFluid’s high shear mixers. The precise control over mixing parameters ensures uniform particle size distribution and homogeneity in the final product. Whether it’s creating stable emulsions, dispersions, or suspensions, users can rely on these mixers to deliver repeatable and reliable results. This consistency is crucial for maintaining product standards and meeting regulatory compliance in industries such as pharmaceuticals, food and beverage, and cosmetics.

Moreover, SeFluid’s high shear mixers are designed to be energy-efficient, contributing to reduced operational costs. The innovative design minimizes energy consumption without compromising on performance, making them an environmentally friendly choice. This reduced energy footprint is particularly advantageous for companies aiming to lower their carbon emissions and enhance sustainability.

Specific applications where SeFluid’s high shear mixers have excelled include the production of stable emulsions in the cosmetics industry, where uniform texture and stability are paramount. In the pharmaceutical sector, these mixers are instrumental in creating fine suspensions, ensuring consistent dosage and efficacy of medications. Additionally, the food and beverage industry benefits from SeFluid’s mixers in the production of smooth sauces and dressings, where maintaining the desired consistency and texture is essential.

Case studies and customer testimonials further highlight the effectiveness and reliability of SeFluid’s high shear mixers. For instance, a leading pharmaceutical company reported a 30% increase in production efficiency after integrating SeFluid’s mixer into their process. Another example is a cosmetics manufacturer who achieved significant improvements in emulsion stability, leading to enhanced product shelf life and customer satisfaction. These real-world scenarios underscore the tangible benefits and superior performance of SeFluid’s high shear mixers.