High Shear Mixing Blade

Introduction of High Shear Mixing Blade

High shear mixing blades are a type of mixing tool that is commonly used in various industrial processes. These blades are designed to create a powerful mixing action, which is ideal for applications that require a high degree of shear force. In this post, we will explore what high shear mixing blades are, how they work, and their various applications.

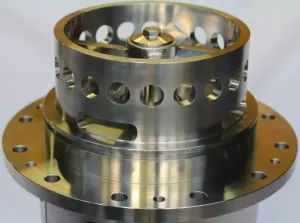

The blades themselves consist of a central hub and multiple arms that extend outwards from the hub. The arms are typically curved or angled to create a mixing action that is both powerful and efficient. The blades are often made of stainless steel or other durable materials to withstand the high stresses and pressures that are generated during the mixing process.

How High Shear Mixing Blades Work

High shear mixing blades work by creating a powerful shearing action that breaks down the ingredients into smaller particles. As the blade rotates, the curved or angled arms push the ingredients towards the outer edge of the mixing vessel. This creates a high degree of turbulence, which results in the ingredients being repeatedly subjected to shearing forces.

The shearing forces generated by the high shear mixing blades cause the particles to collide and break down into smaller sizes. This is beneficial for many applications, as it can result in a more uniform mixture and improved product quality. Additionally, the high shear mixing action can be used to create emulsions, suspensions, and other complex mixtures.

Performance of High Shear Mixing Blades

There are several factors that can affect the performance of a high shear homogenizer. One of the most important is the design of the rotor and stator. The size and shape of the blades can have a significant impact on the intensity of the mechanical force and the resulting mixture. The gap between the rotor and stator is also important because it determines the amount of material that can be processed at one time.

Another factor that can affect the performance of a high shear homogenizer is the viscosity of the material being processed. Higher viscosity materials require more energy to be processed, which can affect the efficiency of the device. In addition, the temperature of the material can also be a factor because high temperatures can affect the stability of the mixture.

Applications of High Shear Mixing Blades

High shear mixing blades are used in a wide range of industrial applications, including food and beverage processing, pharmaceutical manufacturing, and chemical production. Some common applications include:

- Mixing and homogenization of food and beverage products, such as sauces, dressings, and dairy products. High shear mixing can help to create a smooth texture and ensure that the ingredients are evenly distributed.

- Preparation of pharmaceutical products, including creams, gels, and ointments. High shear mixing is often used to ensure that the active ingredients are evenly distributed throughout the product.

- Production of cosmetic products, such as lotions, shampoos, and conditioners. High shear mixing can help to create a smooth, creamy texture that is appealing to consumers.

- Mixing of chemicals, such as polymers, resins, and adhesives. High shear mixing can help to create a uniform mixture and ensure that the ingredients are fully dispersed.

In addition to these applications, high shear mixing blades can also be used in research and development settings to test new formulations and optimize existing processes.

Conclusion

High shear mixing blades are a versatile and powerful mixing tool that is used in a wide range of industrial applications. They work by creating a shearing action that breaks down the ingredients into smaller particles, resulting in a more uniform mixture and improved product quality. Whether you are producing food products, pharmaceuticals, or chemicals, high shear mixing blades can help to optimize your process and ensure that you are producing high-quality products.

Request for Quotation

CONTACT

No 10, Jinhai Rd, Hefei, China 201400

Phone: +86 156 6910 1862

Fax: +86 551 5843 6163

moc.diulfesobfsctd@selas