Industrial High Shear Mixers by SeFluid

SeFluid is a renowned company specializing in the design and manufacturing of high-quality industrial high shear mixers. With a rich history spanning several decades, SeFluid has established itself as a leader in the field of mixing technology. The company’s mission is to provide innovative and reliable mixing solutions that meet the diverse needs of various industries, ensuring optimal performance and efficiency in their processes. SeFluid’s commitment to quality is evident in every aspect of its operations, from research and development to production and customer support.

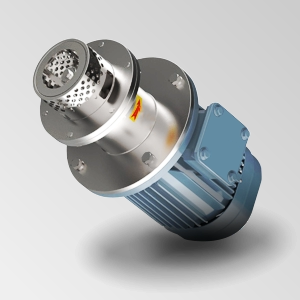

Industrial high shear mixers are critical equipment in many manufacturing processes, where precise and thorough mixing of materials is essential. These mixers are designed to handle a wide range of substances, ensuring that even the most challenging mixtures are uniformly blended. The basic design of a high shear mixer typically includes a rotor-stator assembly, which generates high levels of shear force to break down particles and disperse them evenly throughout the mixture. The components are engineered to withstand rigorous operating conditions, delivering consistent performance and durability.

The operating principles of industrial high shear mixers involve the rotor spinning at high speeds within the stator, creating intense hydraulic shear forces that effectively mix the materials. This process is crucial in applications where standard mixing methods are insufficient, such as in the production of emulsions, suspensions, and dispersions. The precision and efficiency of high shear mixers make them indispensable in industries such as pharmaceuticals, cosmetics, food and beverages, and chemicals.

In industrial processes where the homogenization of materials is paramount, SeFluid’s industrial high shear mixers provide reliable and efficient solutions. These mixers ensure that every batch is consistent in quality, reducing production times and improving product performance. SeFluid’s dedication to innovation and excellence has positioned the company as a trusted partner for businesses seeking advanced mixing technology.

Functionality of SeFluid’s Industrial High Shear Mixers

SeFluid’s industrial high shear mixers are engineered to deliver exceptional performance across a wide spectrum of mixing applications. The core mechanism of these mixers leverages high shear forces to achieve rapid and uniform dispersion of materials. This high shear mixing process involves the use of a rotor-stator assembly, where the rotor rotates at high speeds within the stationary stator. The intense mechanical and hydraulic shear forces generated in this process effectively break down and blend materials into fine particles, ensuring homogeneity and stability of the final product.

SeFluid’s mixers are adept at handling a diverse range of materials, including liquids, semi-solids, and solids. This versatility is made possible through multiple settings and configurations that can be customized to meet specific industrial requirements. For example, the speed of the rotor can be adjusted to achieve the desired shear intensity, making it suitable for both delicate and robust mixing tasks. Furthermore, the mixers can be equipped with various types of rotors and stators, each designed to cater to different viscosities and material properties.

One of the standout features of SeFluid’s industrial high shear mixers is their adaptability. They come with programmable controls that allow for precise adjustments, ensuring optimal mixing conditions for different applications. Whether it’s emulsifying, homogenizing, or dispersing, SeFluid’s mixers provide the flexibility needed for efficient processing. Additionally, the mixers boast robust construction, ensuring durability and longevity even in the most demanding industrial environments.

SeFluid also incorporates several unique technologies that set their mixers apart from competitors. Some models feature patented designs that enhance the mixing efficiency, such as advanced rotor-stator geometries that maximize shear rates while minimizing energy consumption. These innovations not only improve the performance but also contribute to lower operational costs, making SeFluid’s industrial high shear mixers a valuable investment for any production facility.

Advantages of Using SeFluid’s Industrial High Shear Mixers

SeFluid’s industrial high shear mixers offer numerous benefits to industrial users, making them a preferred choice across various sectors. One of the primary advantages is the exceptional efficiency and precision these mixers bring to the mixing process. By utilizing advanced shear forces, SeFluid’s mixers ensure uniform and thorough blending of materials, which is critical for maintaining product consistency and quality.

Durability and longevity are also standout features of SeFluid’s mixers. Constructed from high-quality materials, these mixers are designed to withstand the rigors of continuous industrial use. This durability translates into lower maintenance costs and extended operational life, offering significant cost savings over time. Additionally, the robust design minimizes downtime, enhancing overall productivity.

Another key benefit is the versatility of SeFluid’s industrial high shear mixers. Capable of handling a wide range of materials, from viscous fluids to powders, these mixers are suitable for diverse applications. Whether used in food processing, pharmaceuticals, cosmetics, or chemical manufacturing, SeFluid’s mixers adapt to various production requirements with ease.

Improved product quality is a direct outcome of using SeFluid’s high shear mixers. The homogenization process ensures that all components are evenly distributed, reducing the risk of inconsistencies and defects. This is particularly beneficial in industries where product uniformity is paramount, such as in the production of emulsions, suspensions, and pastes.

Numerous case studies have demonstrated the tangible advantages of SeFluid’s mixers. For instance, a pharmaceutical company reported a 30% reduction in production time and a 15% increase in product yield after integrating SeFluid’s high shear mixers into their process. Similarly, a cosmetics manufacturer noted significant improvements in the texture and stability of their creams and lotions, attributing these enhancements to the superior mixing capabilities of SeFluid’s equipment.

In summary, SeFluid’s industrial high shear mixers provide unmatched efficiency, durability, and versatility, making them an invaluable asset in various industrial applications. Their ability to enhance product quality while offering cost-saving benefits underscores their importance in modern manufacturing processes.

Applications of SeFluid’s Industrial High Shear Mixers

SeFluid’s industrial high shear mixers are indispensable across a diverse array of industries, reflecting their versatility and efficiency. In the pharmaceutical sector, these mixers play a crucial role in processes such as emulsification and homogenization. For instance, the creation of stable emulsions for creams and ointments, as well as the consistent blending of active pharmaceutical ingredients, are achieved seamlessly with SeFluid’s technology. This ensures both product efficacy and safety, which are paramount in pharmaceutical manufacturing.

The food and beverage industry also relies heavily on high shear mixers for various applications. From the production of smooth sauces and dressings to the homogenization of dairy products, SeFluid’s mixers help maintain texture and flavor consistency. A notable example is the reduction of particle sizes in soups and purees, which enhances mouthfeel and shelf-life.

In the cosmetics industry, the demand for high-quality, stable emulsions for lotions and creams is met by SeFluid’s mixers. These mixers ensure that all ingredients are uniformly dispersed, resulting in a product that is both aesthetically pleasing and functional. Additionally, the ability to achieve fine particle size reduction is paramount in producing smooth, luxurious cosmetic products.

The chemical industry benefits from SeFluid’s high shear mixers in processes such as dispersing solid particles into liquids, which is essential in the production of paints, coatings, and adhesives. The mixers’ capability to handle viscous materials and create uniform mixtures ensures product quality and performance.

Testimonials from satisfied clients underscore the reliability and effectiveness of SeFluid’s industrial high shear mixers. One customer from a leading pharmaceutical company notes, “SeFluid’s mixers have significantly improved our production efficiency and product quality.” Another endorsement from a food processing company highlights, “The consistent performance and durability of SeFluid’s mixers have made them a staple in our manufacturing process.”

Overall, SeFluid’s industrial high shear mixers have proven to be a vital component in various industrial settings, offering unparalleled mixing efficiency and product consistency.