High shear mixers are essential equipment in various industries, including pharmaceuticals, food processing, cosmetics, and chemical manufacturing. These mixers are designed to efficiently blend, emulsify, disperse, and homogenize different types of materials. When selecting a high shear mixer for a specific application, several factors need to be considered to ensure optimal performance and productivity. Here are the key considerations in the selection of high shear mixers.

Selection of High Shear Mixer Type

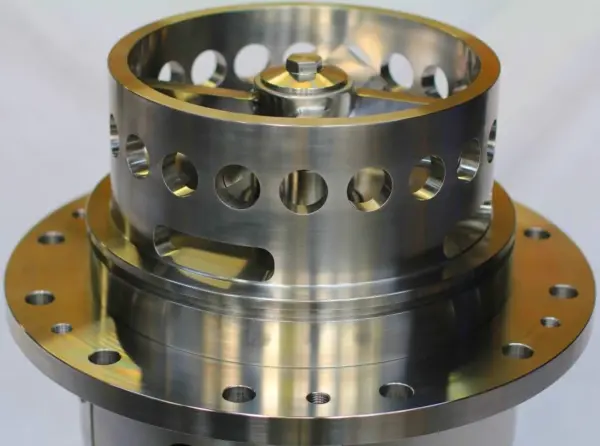

There are different types of high shear mixers available, each with its own advantages and limitations. The most common types include rotor-stator mixers, inline mixers, and batch mixers. Rotor-stator mixers are versatile and suitable for a wide range of applications. Inline mixers provide continuous processing, making them ideal for large-scale production. Batch mixers, on the other hand, are suitable for smaller batches and offer flexibility in terms of operation.

Process Requirements

Understanding the specific process requirements is crucial in selecting the right high shear mixer. Consider the desired mixing intensity, shear rate, viscosity range, and the materials being processed. For example, some applications may require gentle blending, while others may need intense shearing. It’s important to match the mixer’s capabilities with the process requirements to achieve the desired results.

Capacity and Scale

The capacity of the mixer should align with the production requirements. Consider the volume of material to be processed per batch or per hour. High shear mixers are available in a wide range of sizes, from laboratory-scale to large industrial-scale units. Choosing the appropriate size ensures efficient and cost-effective processing.

Material Compatibility

Different high shear mixers are designed to handle specific materials. Consider the characteristics of the materials to be processed, such as viscosity, temperature sensitivity, and chemical compatibility. Some mixers are better suited for low-viscosity liquids, while others can handle high-viscosity pastes or solids. Ensure that the mixer’s construction materials are compatible with the materials being processed to avoid contamination or equipment damage.

Ease of Cleaning and Maintenance

Efficient cleaning and maintenance are essential for maintaining hygienic and reliable operations. Look for high shear mixers that are designed for easy disassembly, cleaning, and reassembly. Consider features such as quick-change tooling, accessibility to internal parts, and the availability of cleaning-in-place (CIP) systems. Easy maintenance procedures and access to spare parts can minimize downtime and enhance productivity.

Safety Features

Safety should always be a top priority when selecting any equipment. High shear mixers can involve high speeds and powerful forces, which present potential hazards. Look for mixers with safety features such as interlocks, emergency stop buttons, and guarding to protect operators and prevent accidents. Additionally, ensure that the mixer complies with relevant safety standards and regulations.

Cost and Return on Investment (ROI)

Consider the initial investment cost of the high shear mixer, as well as the long-term operating costs. Evaluate the durability, reliability, and performance of the mixer to determine its overall value. A higher-quality mixer may have a higher upfront cost but can deliver better performance, increased productivity, and lower maintenance and operating expenses in the long run.

Conclusion

Selecting the right high shear mixer is crucial for achieving efficient and effective mixing processes. By considering factors such as mixer type, process requirements, capacity, material compatibility, ease of cleaning and maintenance, safety features, and cost, one can make an informed decision. Consulting with equipment manufacturers or experts in the field can provide valuable insights and assistance in selecting the most suitable high shear mixer for a specific application.

SeFluid is a leading China manufacturer of fluid processing equipment. Over the past decade, our products have been widely used in numerous fluid applications worldwide. Please click on below relevant products to learn more details or send us an inquiry, and our sales engineers will contact you as soon as possible.

Request for Quotation

CONTACT

No 10, Jinhai Rd, Hefei, China 201400

Phone: +86 156 6910 1862

Fax: +86 551 5843 6163

moc.diulfesobfsctd-196124@selas