Introduction

The work head is a crucial component of a high shear mixer, playing a vital role in its functionality and performance. It is responsible for generating the intense shearing forces required for efficient mixing, emulsification, and dispersion of various substances. In this article, we will explore the importance and key features of the work head in a high shear mixer.

Design and Construction

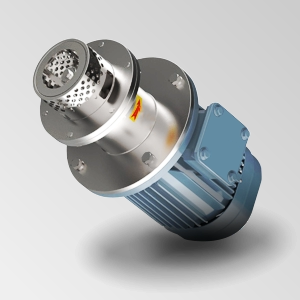

The work head of a high shear mixer is typically designed with precision to ensure optimal performance. It consists of a rotating shaft with multiple mixing elements, such as blades, rotors, or stators. These elements are strategically positioned to create intense shearing forces as the shaft rotates. The design and construction of the work head are critical in achieving the desired mixing results, including uniform dispersion, particle size reduction, and emulsion stability.

Shearing Forces

The primary function of the work head is to generate high shearing forces necessary for effective mixing and processing. As the shaft rotates, the mixing elements create a combination of compression, turbulence, and high-speed fluid flow, resulting in intense shearing action. This shearing action helps break down particles, disperse ingredients, and promote homogeneity within the mixture. The design of the work head, including the number, shape, and arrangement of the mixing elements, influences the magnitude and efficiency of the shearing forces generated.

Versatility and Customization

The work heads of high shear mixers are available in various configurations to accommodate different applications and processing requirements. Manufacturers offer a range of mixing element designs, sizes, and materials to suit specific needs. This versatility allows for customization and optimization of the work head for diverse processes, including emulsification, dispersion, particle size reduction, and blending. By selecting the appropriate work head configuration, operators can achieve desired results and maximize the performance of the high shear mixer.

Easy Maintenance and Cleanability

The work head of a high shear mixer should be designed for easy maintenance and cleanability. It is important to consider factors such as accessibility, removable components, and smooth surfaces to facilitate thorough cleaning and prevent product contamination. Easy disassembly and reassembly of the work head promote efficient maintenance, reducing downtime and ensuring consistent performance.

Compatibility and Integration

The work head of a high shear mixer should be designed for compatibility and integration with other components of the mixing system. This includes considerations for mounting, sealing, and connection to the power source. Well-designed work heads can be easily integrated into existing processing setups or paired with specific vessel types, such as batch or inline systems. Compatibility and integration enhance operational efficiency and enable seamless processing in various applications.

Conclusion

The work head of a high shear mixer is a critical component that determines its mixing performance. Its design, construction, and shearing forces generation are key factors in achieving efficient mixing, dispersion, and emulsification. With versatility, ease of maintenance, and compatibility features, the work head enhances the overall functionality and effectiveness of high shear mixers in various industries and applications.

SeFluid is a leading China manufacturer of fluid processing equipment. Over the past decade, our products have been widely used in numerous fluid applications worldwide. Please click on below relevant products to learn more details or send us an inquiry, and our sales engineers will contact you as soon as possible.

Request for Quotation

CONTACT

No 10, Jinhai Rd, Hefei, China 201400

Phone: +86 156 6910 1862

Fax: +86 551 5843 6163

moc.diulfesobfsctd@selas