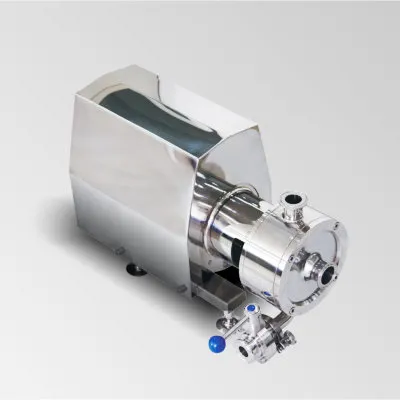

Helical Rotor Pump

Helical rotor pumps, also known as progressive cavity pumps, have gained significant traction in various industries due to their efficiency and versatility. These pumps are specifically designed to handle a wide range of fluids, from highly viscous materials to shear-sensitive substances. SeFluid, a leading provider of innovative pumping solutions, specializes in these advanced pumps, ensuring optimal performance and reliability for diverse applications.

How Helical Rotor Pumps Work

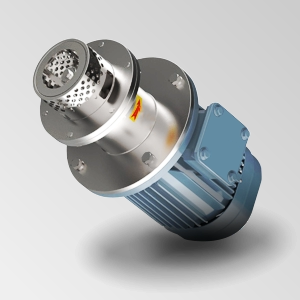

A helical rotor pump consists of a helical rotor and a stator. The rotor, typically made of metal, rotates within the elastomeric stator, creating cavities that progress from the suction to the discharge end of the pump. As the rotor turns, the cavities transport the fluid, ensuring a continuous, smooth flow. This design minimizes pulsation and shear, making these pumps ideal for handling sensitive fluids.

Key Features and Benefits

Versatility: Helical rotor pumps can handle a variety of fluids, including slurries, viscous materials, and abrasive substances. This versatility makes them suitable for industries such as oil and gas, food and beverage, wastewater treatment, and pharmaceuticals.

Efficiency: The unique design of these pumps ensures a high volumetric efficiency. The continuous flow generated by the progressive cavities reduces energy consumption, leading to cost savings in the long run.

Durability: SeFluid’s helical rotor pumps are built to withstand harsh operating conditions. The robust construction and high-quality materials ensure a long service life, even when handling abrasive or corrosive fluids.

Low Maintenance: These pumps have fewer moving parts compared to other types of pumps, which reduces the likelihood of wear and tear. This translates to lower maintenance costs and minimal downtime.

Gentle Handling: The low-shear pumping action is particularly beneficial for applications where preserving the integrity of the fluid is critical, such as in the food and beverage or pharmaceutical industries.

Specification

Applications of Helical Rotor Pumps

Oil and Gas Industry

In the oil and gas sector, helical rotor pumps are employed for transferring crude oil, drilling mud, and other viscous fluids. Their ability to handle high viscosity and abrasive materials makes them indispensable in upstream and downstream operations. SeFluid’s pumps are engineered to meet the stringent demands of this industry, ensuring reliable performance in challenging environments.

Food and Beverage Industry

The gentle handling characteristic of helical rotor pumps makes them ideal for the food and beverage industry. These pumps can transfer delicate products like fruit purees, dairy products, and sauces without compromising their quality. SeFluid’s helical rotor pumps are designed to comply with food safety standards, ensuring hygiene and efficiency in processing applications.

Wastewater Treatment

In wastewater treatment plants, these pumps are used for transferring sludge, slurry, and other waste materials. The ability to handle solids-laden fluids and maintain a consistent flow rate is crucial for efficient wastewater management. SeFluid’s robust and reliable helical rotor pumps contribute to the smooth operation of treatment facilities, helping to meet regulatory standards.

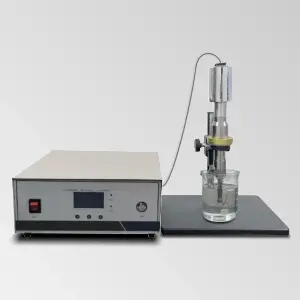

Pharmaceutical Industry

Precision and hygiene are paramount in the pharmaceutical industry. Helical rotor pumps are used for transferring sensitive and sterile fluids, ensuring that the active ingredients are not degraded during the pumping process. SeFluid offers pumps that meet the rigorous standards of the pharmaceutical sector, providing safe and reliable solutions for various applications.

Innovations and Technological Advancements

SeFluid continuously invests in research and development to enhance the performance and efficiency of its helical rotor pumps. Some of the recent innovations include:

Advanced Materials: The use of advanced materials for the rotor and stator improves wear resistance and extends the pump’s lifespan. SeFluid offers a range of materials tailored to specific applications, ensuring optimal performance.

Smart Pump Technology: Integration of smart sensors and control systems allows for real-time monitoring and optimization of pump performance. These technologies help in predictive maintenance, reducing downtime and operational costs.

Energy Efficiency: SeFluid is committed to sustainability, developing energy-efficient pumps that reduce environmental impact. Innovations in rotor and stator design have led to significant improvements in energy consumption.

SeFluid's Commitment to Quality and Customer Service

SeFluid is dedicated to providing high-quality helical rotor pumps that meet the specific needs of its customers. With a focus on innovation, reliability, and customer satisfaction, SeFluid has established itself as a trusted partner in the pumping industry. The company’s commitment to quality is reflected in its rigorous testing and quality control processes, ensuring that every pump meets the highest standards.

In addition to offering superior products, SeFluid provides comprehensive support services, including technical assistance, maintenance training, and after-sales service. This holistic approach ensures that customers receive the best possible solutions and support throughout the lifecycle of their pumps.

Conclusion

Helical rotor pumps play a vital role in a wide range of industries due to their versatility, efficiency, and durability. SeFluid, with its commitment to innovation and quality, offers state-of-the-art helical rotor pumps that cater to diverse applications. By understanding the unique advantages and applications of these pumps, industries can make informed decisions and achieve optimal performance in their operations.