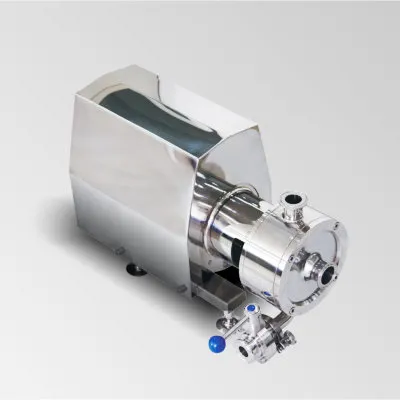

High Shear Emulsifier

Overview of High Shear Emulsifier

In the realm of emulsion processing, achieving optimal product quality and consistency is of paramount importance. High shear emulsifiers have emerged as indispensable tools for industries ranging from food and beverage to pharmaceuticals, cosmetics, and beyond. These specialized devices harness the power of intense mechanical forces to create stable, homogeneous emulsions with exceptional precision and efficiency.

Understanding High Shear Emulsification

Emulsions are mixtures of two or more immiscible liquids, where one liquid is dispersed in the other in the form of tiny droplets. Achieving a stable emulsion requires overcoming the natural tendency of these liquids to separate, a process facilitated by emulsifiers. High shear emulsifiers take this process a step further by subjecting the liquids to intense shear forces, which break down the dispersed phase into extremely fine droplets, substantially increasing the surface area available for emulsification.

Working Principles of High Shear Emulsifiers

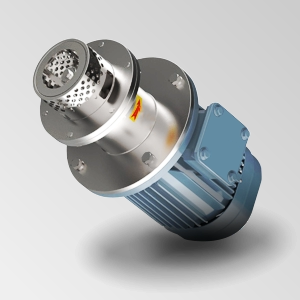

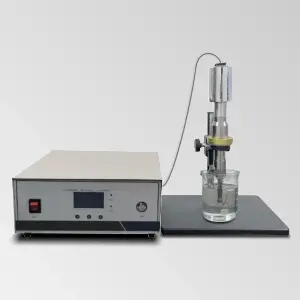

High shear emulsifiers typically consist of a rotor and a stator assembly, where the rotor spins at high speeds within the stator. The liquids to be emulsified are fed into this high-shear zone, where they are subjected to intense mechanical forces, including shear, cavitation, and impingement. These forces work in synergy to break down the dispersed phase into ultra-fine droplets, promoting thorough mixing and emulsification.

The rotor and stator designs can vary depending on the specific application and desired emulsion characteristics. Some emulsifiers feature multiple shear zones or stages, allowing for precise control over droplet size distribution and emulsion homogeneity.

Specification

- power: 1.5-37kw

- capacity: 20-5000 L/batch

- work head shape: Tooth, hole

- material: SS304, SS316

Applications Across Industries

High shear emulsifiers find widespread applications in various industries due to their ability to create stable, high-quality emulsions tailored to specific product requirements:

- Food and Beverage Industry: From mayonnaise and salad dressings to dairy products and beverages, high shear emulsifiers ensure consistent texture, mouthfeel, and shelf life.

- Pharmaceutical and Cosmetic Industries: Emulsions are crucial in the formulation of creams, lotions, and topical preparations. High shear emulsifiers facilitate the production of uniform, stable emulsions with desired release profiles and sensorial properties.

- Chemical and Petrochemical Industries: High shear emulsifiers are employed in the production of emulsions for various applications, including lubricants, coatings, and polymer processing.

- Renewable Energy Sector: Biofuel production often involves the emulsification of feedstocks, and high shear emulsifiers play a crucial role in optimizing process efficiency and yield.

Benefits of High Shear Emulsification

Incorporating high shear emulsifiers into industrial processes offers numerous advantages:

- Superior Emulsion Stability: The intense shear forces generated by these emulsifiers result in ultra-fine droplet sizes, contributing to enhanced emulsion stability and extended shelf life.

- Improved Product Consistency: High shear emulsifiers ensure uniform droplet size distribution, leading to consistent product quality and performance.

- Efficient Process: The high-energy input provided by these emulsifiers facilitates rapid emulsification, reducing processing time and increasing productivity.

- Versatility: High shear emulsifiers can handle a wide range of viscosities and emulsion types, making them versatile tools for diverse applications.

- Scalability: These emulsifiers are available in various sizes and configurations, allowing for seamless scaling from pilot-scale to large-scale industrial production.

Factors to Consider in Selecting High Shear Emulsifiers

When selecting a high shear emulsifier for your application, several factors should be taken into consideration:

- Emulsion Characteristics: Evaluate the desired droplet size distribution, viscosity, and stability requirements of your emulsion to determine the appropriate emulsifier configuration.

- Production Scale: Choose an emulsifier with the appropriate capacity and throughput to match your production volumes and demands.

- Materials of Construction: Ensure that the emulsifier’s materials are compatible with the liquids being processed and meet any regulatory requirements for your industry.

- Ease of Cleaning and Maintenance: Consider emulsifiers with designs that facilitate efficient cleaning and maintenance to minimize downtime and ensure consistent performance.

- Energy Efficiency: Evaluate the energy consumption and operating costs associated with different emulsifier models to optimize your overall production efficiency.