Definition of Screw Decanter Centrifuge

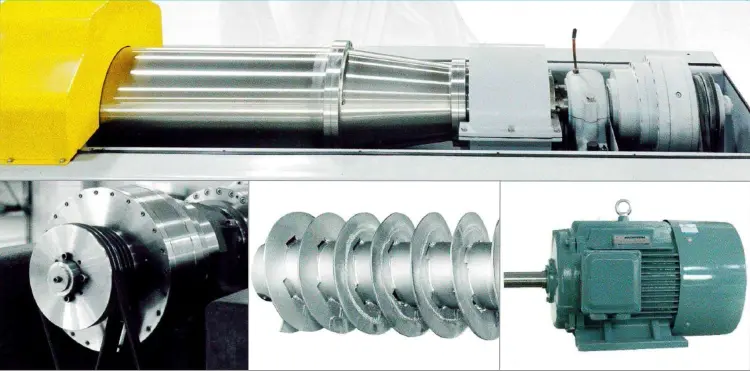

A screw decanter centrifuge is a high-performance separation equipment that utilizes centrifugal force to separate substances with different densities. It features a continuous operation design, making it efficient for the processing of liquid-solid mixtures and liquids with varying specific gravities. The screw conveyor system within the centrifuge helps in the efficient transportation and dewatering of solids, while the conical bowl allows for effective separation due to the increasing centrifugal force towards the outlet.

SeFluid’s SELW series showcases exceptional versatility in concentrating, dewatering, and classifying suspensions containing solid particles. This range extends from minuscule microns to larger millimeters in particle size. In industries such as chemicals, pharmaceuticals, wastewater treatment, and printing and dyeing, the screw decanter centrifuge emerges as an indispensable tool. SeFluid’s SELW series embodies this necessity, offering unparalleled performance across diverse applications.

specification

Power

11-37 kw

Capacity

0.5-40 m³/h

Speed

2700-4800 rpm

Separation Factor

2100-3000

How Screw Decanter Centrifuge Works

The work principle of a screw decanter centrifuge is based on the principles of sedimentation and centrifugal force. It involves the rotation of a bowl and a screw conveyor within the centrifuge to separate solid particles from liquids. Here’s a general overview of how the machine works:

Feed Introduction

The feed, which is a mixture of solid and liquid, is introduced into the centrifuge through an inlet pipe. The feed enters the rotating bowl of the centrifuge.

Sedimentation

As the feed enters the bowl, the high-speed rotation of the centrifuge generates centrifugal force. This force causes the solid particles in the feed to settle against the bowl wall due to their higher density. Meanwhile, the liquid phase, which has a lower density, forms a clear layer above the settled solids.

Screw Conveyor Operation

Inside the bowl, there is a screw conveyor that rotates at a different speed than the bowl itself. The screw conveyor consists of several sections: the feed section, the clarification section, and the dewatering section.

Solid Conveyance

The screw conveyor, rotating at a slightly lower speed than the bowl, moves the settled solids along the length of the bowl. The feed section of the screw conveyor collects the settled solids from the bowl’s wall and transports them towards the clarification section.

Clarification

In the clarification section of the screw conveyor, additional separation takes place. The solids continue to settle, and any remaining liquid is forced out through small openings in the conveyor. This allows further liquid-solid separation as the liquid passes through the openings while the solids are conveyed forward.

Dewatering

In the dewatering section, the settled solids are progressively compressed and dewatered as they move closer to the discharge end of the centrifuge. The compression and reduced conveyor pitch in this section help increase the dewatering efficiency.

Discharge

At the discharge end, the dewatered solids are pushed out of the centrifuge through an outlet. The separated liquid, known as the centrate or filtrate, exits the centrifuge through a separate outlet.

This process of continuous sedimentation, solid conveyance, clarification, and dewatering allows the screw decanter centrifuge to achieve efficient separation of solids from liquids. The rotational speed, differential speed between the bowl and screw conveyor, and the design of the conveyor flighting all contribute to the effective operation of the centrifuge.

Benefits of screw decanter centrifuge

Screw decanter centrifuges offer several benefits in various industrial applications. Here are some of the key advantages:

Efficient solid-liquid separation

Screw decanter centrifuges are highly effective at separating solid particles from liquids. They can handle a wide range of solid concentrations and particle sizes, making them versatile for different applications. The centrifugal force generated by the high-speed rotation allows for efficient sedimentation and dewatering of solids.

Continuous operation

These centrifuges are designed for continuous operation, which means they can handle a continuous feed stream and produce a continuous discharge of separated solids and liquid. This feature makes them suitable for industrial processes that require uninterrupted operation.

High throughput

Screw decanter centrifuges typically have high processing capacities, allowing for large volumes of feed to be processed within a relatively short time. This high throughput makes them suitable for applications where a significant amount of solids needs to be separated from liquids.

Versatility

These centrifuges can handle a wide range of applications across various industries. They are commonly used in wastewater treatment, chemical processing, food and beverage production, pharmaceuticals, mining, and many other sectors. The ability to handle different types of fluids and solids makes them adaptable to different process requirements.

Dewatering capability

Screw decanter centrifuges excel at dewatering solid materials. By compressing and conveying the settled solids along the length of the centrifuge, they can effectively remove excess liquid, resulting in drier and more concentrated solids. This dewatering capability is beneficial for waste management, sludge treatment, and other applications where reducing moisture content is essential.

Lower energy consumption

Compared to other solid-liquid separation methods, such as filter presses or belt filters, screw decanter centrifuges often have lower energy consumption. They require less power to achieve the desired separation efficiency, making them energy-efficient and cost-effective over the long term.

Reduced footprint

The centrifuges typically has a compact design, requiring less floor space compared to other separation equipment. This is advantageous in facilities where space is limited or needs to be optimized.

Feature of SeFluid's Screw Decanter Centrifuge

SeFluid’s screw decanter centrifuge offers numerous features in industrial applications. With its exceptional features, it stands out as an efficient and reliable separation solution.

1

One of the notable features of SeFluid’s screw decanter centrifuge is its ability to achieve low residual moisture content in the separated solids. This ensures that the dewatered solids have a significantly reduced water content, making them easier to handle and dispose of.

2

The screw decanter centrifuge manufactured by SeFluid boasts a large length-to-diameter ratio, reaching an impressive 4.4. This design feature enhances the sedimentation and separation process, allowing for improved efficiency and a higher capacity for solid-liquid separation.

3

The small differential speed system employed by SeFluid’s screw decanter centrifuge is another highlight. This system ensures precise control over the speed difference between the bowl and the screw conveyor, optimizing the separation process and achieving exceptional separation results.

4

Operating at a noise level below 65 dB(A), SeFluid’s screw decanter centrifuge demonstrates low noise emissions. This feature is beneficial in industrial settings where noise reduction is crucial for a comfortable working environment.

5

In addition to its performance advantages, SeFluid’s screw decanter centrifuge is also energy-efficient, consuming minimal power. This not only reduces operational costs but also contributes to energy savings and sustainability. Moreover, the low power consumption translates into lower maintenance costs, making it a cost-effective solution.

6

SeFluid’s screw decanter centrifuge is built with precision-engineered dynamic components and a carefully balanced operating speed, ensuring smooth and stable operation. This reliability minimizes downtime and maintenance requirements, enhancing overall productivity.

7

With a high separation coefficient and a large processing capacity, SeFluid’s screw decanter centrifuge excels at achieving efficient and effective separation of solids from liquids. It can handle substantial volumes of feed, making it suitable for applications that demand high throughput.

8

Furthermore, SeFluid’s screw decanter centrifuge offers the advantage of continuous processing and a high degree of automation. Its seamless operation allows for uninterrupted production, while advanced automation features enable precise control and monitoring, enhancing process efficiency.

Summary

Applications of Screw Decanter Centrifuge

Screw decanter centrifuges have a wide range of applications across various industries. Their ability to separate solid particles from liquids makes them valuable in many processes that require efficient solid-liquid separation. Here are some common applications of screw decanter centrifuges:

Wastewater Treatment

Screw decanter centrifuges are extensively used in wastewater treatment plants. They can effectively separate solid sludge from wastewater, allowing for the removal of contaminants and the production of clean water for discharge or reuse. The dewatered sludge can be further processed for disposal or used for energy generation.

Chemical Industry

In the chemical industry, screw decanter centrifuges are utilized for various processes, including the separation of solids from liquid suspensions, clarification of chemical solutions, and dewatering of chemical sludge. They play a crucial role in achieving product purity, recovering valuable chemicals, and minimizing waste generation.

Food and Beverage Industry

Screw decanter centrifuges are employed in the food and beverage industry for processes such as clarification of fruit juices, extraction of oils from seeds, separation of solids from dairy products, and dewatering of food waste. These centrifuges help maintain product quality, improve production efficiency, and reduce waste.

Petrochemical Industry

Screw decanter centrifuges find applications in the petrochemical industry for the separation of solids from various hydrocarbon streams. They are used in processes such as oil sludge treatment, removal of catalyst particles from chemical reactions, and clarification of petroleum products.

Mining and Minerals Processing

In mining and minerals processing, screw decanter centrifuges are utilized for dewatering and separation of fine particles from slurries. They are commonly used in coal preparation plants, mineral processing plants, and tailings management to recover valuable minerals and reduce water content in the processed materials.

Pharmaceutical Industry

Screw decanter centrifuges play a crucial role in pharmaceutical manufacturing processes. They are employed for the separation of solids from fermentation broths, purification of pharmaceutical intermediates, and recovery of active ingredients from plant extracts.

Environmental Remediation

Screw decanter centrifuges are utilized in environmental remediation projects for the treatment of contaminated soil, sediment, and groundwater. They help separate and dewater the solid contaminants, allowing for proper disposal or further treatment.

Oil and Gas Industry

In the oil and gas industry, screw decanter centrifuges are used for the separation of oil and water emulsions, removal of solids from drilling mud, and dewatering of oil sludge generated during oilfield operations. They contribute to the efficient processing of crude oil, wastewater treatment, and environmental compliance.

Request for Quotation

NEWS

contact

No 28, Fengxia Rd, Hefei, Anhui Province, China 201400

Phone: +86 156 6910 1862

Fax: +86 551 5843 6163

moc.diulfesobfsctd-79d832@selas