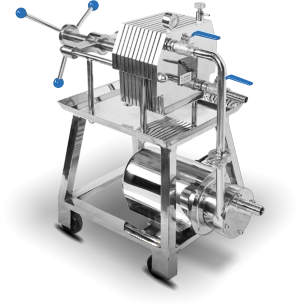

Introduction of Plate and Frame Filter Press

The plate and frame filter press is a kind of equipment applicable to the process operation with the requirements of fine filtration and semi-fine filtration. It is ideal for the applications of purification, sterilization and defecation with sealed filtration in the liquid processing with low viscosity and little slagging content under the concentration of 50%. By directly adopting microporous filtration film, it can realize the sterile filtration without passing the microporous film.

This equipment has characteristics such as large filtration area, large flow and wide applicable range, so it is widely used in the fields of pharmacy, chemical industry and food etc. The effect will be better if used for filtration of injection liquid medicine in pharmacy factories.

SeFluid’s hygienic plate and frame filter press series is made of high quality 304 or 316L stainless steel, corrosion-resistant and durable, and can be widely used in pharmaceutical, food, beverage, water treatment, brewing, petroleum, chemical, environmental protection and other industries, and is the latest equipment for filtration, clarification, purification and sterilization of various types of liquids.

specification

Power

0.55-3 kw

Capacity

0.8-20 t/h

Layer Quantity

10-26

Material

SS304, SS316

Advantages of Plate and Frame Filter Press

Plate and frame filter presses have several advantages, including:

Sealing

The use of convex plate filter plate effectively increases the water conductive cross-sectional area, reduces the liquid filtration, circulation resistance, so that the liquid arbitrary flow to improper dead ends, and can maintain the stability of liquid performance. The convex plate makes the filter material (filter membrane, filter paper, etc.) is not easy to break, and prolongs the service life of various filter media.

Filtering Performance

When a plate and frame filter press is working, the sealing rings are compressed tightly. There is no loss of liquid, with good clarity of the liquid and good sterilization effect (especially good for microporous filter membrane). It can ensure the proceeded material to be in a sterile environment to prevent the material from being contaminated. It has the ability to achieve purification, sterilization, clarification and other fine filtration requirements.

Efficient filtration

This kind of equipment utilizes a series of filter plates and frames to trap and remove solids from liquids. This process results in very efficient filtration, with high levels of solids removal and minimal liquid loss.

Versatility

Plate and frame filter presses can be used for a wide range of applications, from food and beverage processing to pharmaceuticals and chemicals. The filter plates and frames can be customized to suit specific filtration needs, such as different sizes and materials.

Easy to clean

This kind of equipment is designed for easy cleaning and maintenance. The filter plates and frames can be easily removed for cleaning and replacement, and the press itself can be cleaned using standard cleaning procedures.

Hygienic

This machine is designed to meet strict hygiene standards, making them ideal for use in the food and beverage industry. The filter plates and frames are made of materials that are easy to sanitize, and the press is designed to prevent contamination.

Feature of SeFluid's Plate and Frame Filter Press Series

1

Food grade tri-clamp connect, easy to remove and clean the machine.

2

With stainless steel liquid transfer pump, low power consumption.

3

Bifold ring for inlet: sturdy, sealed and easy to disassemble and clean.

4

Big flow rate based on filter plate size and 10 layers.

5

Large filtration area, good sealing performance, no penetration.

6

High precision filtration for 0.2+ microns particles in one-time.

Request for Quotation

NEWS

CONTACT

No 10, Jinhai Rd, Hefei, China 201400

Phone: +86 156 6910 1862

Fax: +86 551 5843 6163

moc.diulfesobfsctd@selas