Introduction of Powder Liquid Mixer

The powder liquid mixer is a kind of machine for high efficiency mixing of powder and liquid. In the work of mixing, most applications are the mixing of powder and liquid. This will involve the mixing efficiency and agglomeration. During the case of flour into water, if powder fineness is very high, lumps will appear in combining and mixing. As a result, the users must take complex equipment and a lot of extra work to prevent this.

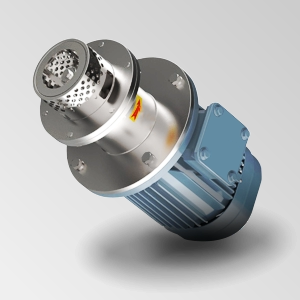

SeFluid’ high shear powder liquid mixer series can generate vacuum and introduces the powder directly into the liquid stream. Then, the powder is instantly and uniformly wetted when it first touches the liquid and is quickly dispersed.

Not only is the powder wetted, but it can also be dispersed into the liquid under vacuum. So, the machine can prevent large amounts of air from entering. Moreover, it can avoid agglomeration and has better reaction effect. Therefore, higher material utilization and better product quality will be obtained. SeFluid’s high shear powder liquid mixer has a high degree of modular integration. In conclusion, it saves a lot of piping and process steps while minimizing production costs.

specification

Power

5.5-75 kw

Speed

2900 rpm

Capacity

10-70 m³/h

Material

SS304, SS316

Principle of Powder Liquid Mixer

In the powder liquid mixer, there is a set of rotors. It rotates at high speed to generate vacuum. After that, the powder is evenly sucked into the working chamber via the suction pipe. And the powder is evenly distributed in the fast-flowing liquid stream. In the working head, the powder is completely wetted without agglomerating lumps.

Moreover, there are no crusts formed on the surface of the liquid stream, the stirring shaft and the vessel wall. In contrast, conventional processes tend to form hard crusts. Therefore, this powder liquid mixer can greatly improve the mixing quality. Because of no powder residue and there is vacuum occurs, the machine can reduce the dust. Therefore, there will be no need of the environmental protection methods.

Features of Powder Liquid Mixer

1

Sanitary design, lower noise, smooth operation.

2

Compact structure, easy to clean and disassemble.

3

With self-priming, no need of feeding pump.

4

No pollution to raw materials, modular design, ideal for industries with high.

5

Large processing capacity, high mixing efficiency, effective avoidance of agglomeration and reduction of dust pollution.

6

Inline powder absorption to avoid dust pollution. Simple and fast for solid-liquid dispersion, emulsification and dissolution processing.

Benefits of SeFluid's Powder Liquid Mixer

In the work of material mixing, most of the mixing is the mixing of powder and liquid. And the combination of powder and liquid, will involve the mixing efficiency and agglomeration of the problem. As in the case of flour into water, if the fineness of the powder is very high, in the process of combining and mixing with the liquid, it will inevitably produce lumps. In traditional mixing processes, complex equipment and a lot of extra work and time are required to prevent this.

Now, a single SeFluid high shear powder-liquid mixer can perform all process steps: dust-free and loss-free suction tube feeding, rapid powder addition, dosing, wetting and complete agglomeration-free dispersion mixing. Not only is the powder wetted, but it can also be dispersed into the liquid under vacuum to prevent large amounts of air from entering. Avoid agglomeration, better reaction effect, higher material utilization and better product quality. The equipment has a high degree of modular integration, which saves a lot of piping and process steps while minimizing production costs.

Request for Quotation

NEWS

CONTACT

No 28, Fengxia Rd, Hefei, Anhui Province, China 201400

Phone: +86 156 6910 1862

Fax: +86 551 5843 6163

moc.diulfesobfsctd-246fd4@selas