Peristaltic Hose Pump

SeFluid is a leading peristaltic hose pump manufacturer in China. We adhere to the highest product quality standards. In addition, during the lifetime use of our products, we ensure complete after-sales technical support to serve users with confidence and satisfaction.

OVERVIEW OF PERISTALTIC HOSE PUMP

Peristaltic hose pump is a kind of leak free positive displacement pump that operates by squeezing and releasing a flexible hose to generate flow. It uses a rotating mechanism with rollers or shoes that compress the tube against a fixed housing or track, creating a series of occlusions that move along the length of the tube. As the occlusion progresses, it pushes the fluid trapped in the tube forward. Due to the special working principle, users also call it tube pump or squeeze pump.

How the peristaltic hose pump works

A peristaltic hose pump operates on a simple yet effective principle: it uses rollers or shoes to compress a flexible hose or tube, creating a series of positive displacements to move fluid. Here’s a breakdown of how it works:

Flexible Hose or Tube: The pump contains a flexible hose or tube made from materials like silicone, rubber, or thermoplastics. This hose is the only part of the pump that comes into contact with the fluid being pumped.

Rollers or Shoes: Inside the pump, there are typically rollers or shoes arranged around the circumference of the hose. These rollers can be motorized or mechanically driven.

Compression: As the rollers rotate, they compress the flexible hose against a rigid housing or track. This compression creates a series of sealed chambers along the length of the hose.

Fluid Movement: When a chamber is compressed, the volume of the hose decreases, forcing the fluid inside to move forward. As the rollers continue to rotate, they move along the length of the hose, sequentially compressing and expanding each chamber.

Continuous Flow: The sequential compression and expansion of the hose create a pulsating flow of fluid. By adjusting the speed of the rollers and the size of the hose, the pump can control the flow rate and pressure of the fluid.

No Contact with Pump Components: Since the fluid only comes into contact with the inside surface of the hose, there is minimal risk of contamination or damage to the pump components. This makes peristaltic pumps suitable for pumping delicate or abrasive fluids, as well as for applications requiring sterile conditions.

Overall, the peristaltic hose pump’s design offers several advantages, including gentle pumping action, self-priming capabilities, and the ability to handle viscous, shear-sensitive, or abrasive fluids with ease.

Specification

- Pressure: 0.8-1.6 Mpa

- Capacity: 60-80000 L/h

- Hose Diameter: 10-125 mm

- Hose Material: NR, EPDM, NBR, CSM

Advantages of Industrial Peristaltic Hose Pump

Industrial peristaltic hose pumps offer several advantages, making them popular choices for various applications across industries. Here are some of the key advantages:

Gentle Pumping Action: Peristaltic pumps provide a gentle pumping action since the fluid only comes into contact with the interior surface of the hose or tube. This feature makes them ideal for handling shear-sensitive fluids, delicate substances, and fluids containing solids without damaging or altering the product.

Versatility: These pumps can handle a wide range of fluids, including corrosive chemicals, abrasive slurries, viscous liquids, and even fluids containing suspended solids. The compatibility of the pump’s materials with different fluids can be easily customized based on the specific requirements of the application.

Self-Priming: Peristaltic pumps are typically self-priming, meaning they have the ability to create a vacuum and draw fluid into the pump without the need for manual priming or additional equipment. This feature simplifies operation and maintenance, especially in applications where the pump may need to start and stop frequently.

Reversible Operation: Many industrial peristaltic pumps offer reversible operation, allowing the direction of fluid flow to be easily changed. This capability is useful for applications requiring bi-directional pumping or for clearing blockages by running the pump in reverse.

Dry Running and Run-Dry Protection: Peristaltic pumps can run dry for short periods without damage to the pump or the fluid being pumped. Additionally, some models feature run-dry protection systems that automatically shut off the pump if it detects a lack of fluid, preventing damage to the pump components.

Accurate and Repeatable Flow: Peristaltic pumps offer precise control over flow rates, making them suitable for applications where accurate dosing or metering is required. The positive displacement pumping mechanism ensures consistent flow rates, even with varying fluid viscosities or system pressures.

Minimal Maintenance: Peristaltic pumps have a simple design with fewer moving parts compared to other types of pumps, reducing the need for maintenance and minimizing downtime. Additionally, since the pumped fluid only contacts the inside surface of the hose or tube, there is minimal risk of contamination or component wear.

Hygienic and Sterile Pumping: The design of peristaltic pumps allows for easy sterilization and cleaning, making them suitable for hygienic and sterile applications in industries such as pharmaceuticals, biotechnology, and food processing.

In summary, industrial peristaltic hose pumps offer efficient, reliable, and cost-effective pumping solutions for a wide range of fluid handling applications, making them a preferred choice for many industries.

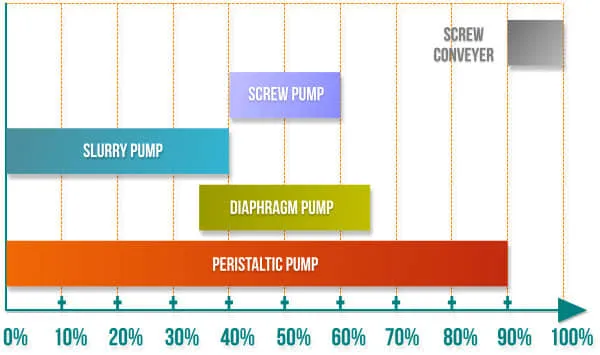

What fluidity range peristaltic pump can handle?

A peristaltic hose pump can manage the broadest range of fluidity, from water to nearly powder-like materials. It is particularly suited for mediums that lack flowability, such as mud, making it the optimal choice when the medium’s liquid content is a critical factor.

What Fluid Types Peristaltic Hose Pump Can Handle?

Peristaltic hose pumps are known for their versatility and ability to handle a wide range of fluids. They are commonly used in various industries and applications due to their gentle pumping action and the ability to handle both corrosive and non-corrosive fluids. Here are some fluid types that peristaltic hose pumps can typically handle:

- Abrasive Fluids: Peristaltic hose pumps are suitable for handling a wide range of liquids, including water, chemicals, solvents, acids, bases, oils, slurries, suspensions, and viscous fluids.

- Ideal for Shear Sensitive Fluids: The pumps are gentle and provide low shear pumping, making them suitable for handling shear-sensitive fluids such as pharmaceuticals, biotech products, food and beverages, and delicate emulsions.

- High-Viscosity Fluids: The pumps are capable of pumping fluids with high viscosity, including thick and sticky substances such as adhesives, pastes, gels, and creams.

- Hazardous & Corrosive Fluids: This type of pump offers excellent chemical resistance, making them suitable for handling hazardous and corrosive fluids including acids, alkalis, solvents, and aggressive chemicals.

- Clean Fluids: Peristaltic hose pumps can handle clean fluids including water, beverages, juices, and liquid food products.

Features of SEP Industrial Peristaltic Hose Pump Series

Compared with other international peristaltic pump brands, our products have many unique features. This makes SeFluid’s products more competitive compared to competitors’ products. Through many years of market development, we have won more and more users.

Long Life Hose

A hose is the core component of an industrial peristaltic hose pump. Generally, there are three layers on the hose: the inner layer, middle layer, and outer layer. SeFluid’s hoses have an inner layer of special rubber. The high-quality inner rubber is specially designed for applications with corrosive and abrasive fluids. The middle layer is made of high-quality nylon for reinforcement, enabling the hose to withstand pressures up to 16 bars and offering excellent fatigue resistance.

The outer layer is made of high-quality, wear-resistant rubber, which strengthens the hose and enhances its wear resistance, allowing it to withstand frequent rolling and high temperatures generated by friction. Moreover, SeFluid uses high precision equipment to machine each hose, ensuring a perfect fit for the pump.

No Need for Lubricant

In the current market, most industrial peristaltic hose pump brands use a sliding shoe as the squeezing device. The contact between the squeezing device and the hose involves sliding friction, requiring a large amount of lubricant to reduce hose damage. Users need to replace this lubricant after extended use or when replacing the hose, a process that is cumbersome, time-consuming, and costly. Additionally, replaced lubricant can potentially contaminate the environment.

Once a hose reaches the end of its service life, it may rupture unexpectedly. Lubricant could then penetrate the pumped fluid, leading to serious contamination, particularly in industries such as pharmaceuticals or foodstuffs.

SeFluid’s pumps, however, use rollers as the squeezing device, replacing sliding friction with rolling friction. This eliminates the need for lubricant, resulting in lower maintenance costs, easier hose replacement, reduced downtime, and no risk of environmental contamination.

High Performance Gearbox

The gearbox is another crucial component of the peristaltic hose pump, significantly influencing its lifespan. It increases the torque of the central shaft by reducing the motor speed, driving the pump rotor to compress the hose and transfer the material.

SeFluid pumps use top brand gearboxes, known for their small size, high torque, long life, and quiet operation. Each gearbox is carefully regulated and tested before delivery, ensuring the pumps operate reliably throughout their lifetime without requiring special or additional maintenance.

Applications of Peristaltic Hose Pump

Peristaltic hose pumps have a variety of applications across different industries due to their unique advantages, such as gentle pumping action, ability to handle a wide range of fluids, and excellent chemical resistance. Here are some common applications of peristaltic hose pumps:

Pharmaceutical Industry: They are used for transferring and dosing sensitive pharmaceutical products, including medicines and vaccines, without contamination.

Food and Beverage Industry: Ideal for pumping a variety of food products, such as sauces, syrups, and beverages, without altering their taste or quality.

Chemical Processing: Effective for handling corrosive and aggressive chemicals, solvents, and acids in processes that require precise dosing and transfer.

Environmental Technology: Used in wastewater treatment plants for the controlled dosing of chemicals and the transfer of sludge.

Medical and Laboratory Research: Employed for precise and gentle handling of samples, reagents, and other laboratory fluids.

Cosmetics Industry: Suitable for the transfer of creams, lotions, and other cosmetic products without degrading their properties.

Paint and Ink Manufacturing: Capable of pumping high-viscosity materials like paints, coatings, and inks.

Agriculture: Used for dosing fertilizers, pesticides, and other agrochemicals in a controlled and precise manner.

Mining: Employed in the transfer of slurries and other abrasive materials in mining operations.

Petrochemical Industry: Utilized for the safe and reliable transfer of petroleum products and other hazardous materials.

Water Treatment: Used for the dosing of water treatment chemicals and the transfer of clean water in various processes.

Pulp and Paper Industry: Effective in handling the thick and viscous substances used in papermaking processes.

Peristaltic hose pumps are valued for their ability to maintain the integrity of the fluid being pumped, which makes them a versatile choice for many applications where product quality and safety are paramount.