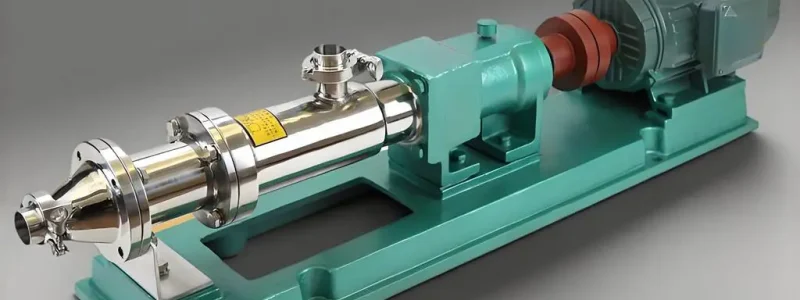

Progressive Cavity Pump

Introduction

A progressive cavity pump (PCP) is a type of positive displacement pump designed for efficient and gentle fluid transfer. Its unique helical rotor and stator mechanism generates a continuous, non-pulsating flow. As the rotor turns within the elastomeric stator, cavities are formed, progressing along the axis to propel viscous fluids with minimal shear force. PCPs are versatile, handling substances ranging from liquids to semi-solids, making them ideal for industries like oil and gas, wastewater treatment, and food processing. Their ability to maintain consistent flow rates, handle abrasive materials, and operate smoothly with high viscosity fluids distinguishes Progressive Cavity Pumps in various applications.

At SeFluid, we offer a variety of progressive cavity pumps that are specifically designed to meet the unique needs of our customers. Our pumps are known for their durability, energy efficiency, and ability to maintain a consistent flow rate, making them a reliable choice for any application. Trust SeFluid for all of your progressive cavity pump needs.

Specification

Power: 0.37-7.5 kw

Capacity: 1-30 m³/h

Flow head: 8-36 m

Material: SS304, SS316

Working Principle of Progressive Cavity Pump

A progressive cavity pump, also known as a PC pump or an eccentric screw pump, operates on the principle of positive displacement. It is widely used for transferring and metering fluids with varying viscosities, including shear-sensitive, abrasive, and stringy materials. Here’s how it works:

Rotor-Stator Assembly: The heart of a progressive cavity pump is its rotor-stator assembly. The rotor is a helical-shaped metal screw (with one or more lobes) that rotates within a precisely machined rubber or elastomer-lined stator, which has a slightly larger helical cavity.

Flow Generation: As the rotor turns inside the stator, it creates a series of small, fixed-volume cavities that progress from the suction to the discharge end of the pump. These cavities move along the length of the pump without changing volume, effectively ‘squeezing’ fluid through.

Suction and Discharge: Fluid enters the pump at the inlet, fills the cavities formed between the rotor and stator, and is carried forward due to the rotation. The cavities decrease in size as they approach the discharge end, which forces the fluid out at a steady, continuous flow rate.

Low Shear: Because of the gentle pumping action, progressive cavity pumps minimize shear stress on the pumped fluid, making them suitable for applications where maintaining product integrity is crucial, such as food processing or chemical slurries.

Self-priming: They are inherently self-priming and can handle liquids containing solids up to a certain size, depending on the design and clearance between the rotor and stator.

Speed Control: By adjusting the speed of the rotor, the output flow rate can be controlled accurately, allowing for precise dosing and metering operations.

Seal-less Design: The seal-less construction of progressive cavity pumps eliminates the need for traditional mechanical seals, reducing maintenance requirements and preventing leaks.

In summary, a Progressive Cavity Pump functions by creating a series of progressing cavities between the rotor and stator, which consistently and gently transport fluid from the suction to the discharge end without causing significant agitation or degradation to the fluid properties.

Features

SeFluid’s hygienic progressive cavity pump is a cutting-edge fluid handling solution that boasts an array of advanced features, designed to cater to the most stringent hygienic requirements across various industries. Here are some key attributes:

- Low Inertial Force: The rotating parts of SeFluid’s pump exhibit low inertial forces, making them ideally suited for high-speed operations without compromising efficiency or stability.

- Reduced Sensitivity: Unlike many other rotary pumps, this model demonstrates increased resilience against incoming gas and dirt contamination, ensuring consistent performance even in challenging environments.

- Smooth Flow and Vibration Control: It provides uniform and continuous flow with minimal vibration and noise, ensuring a smooth-running operation devoid of end-flow pulsation and pulsatility.

- Bi-directional Operation: This hygienic pump offers both forward and reverse running directions, enabling versatile use and flexibility in process design.

- Multi-phase Handling Capability: It excels at pumping multi-phase fluids containing a mix of liquid, gas, and solid content, showcasing its robust versatility and reliability.

- Exceptional Suction and Self-priming: With outstanding suction and self-priming capabilities, it can handle diverse liquids and slurries with ease, enhancing overall productivity and reducing downtime.

- Sanitary Design: SeFluid’s progressive cavity pump adheres to strict sanitary standards, featuring a flash protection cover that safeguards against contamination risks and upholds the highest levels of hygiene.

- High Viscosity and Solid-handling: It has the ability to pump fluids with viscosities up to 50000 cps and can manage solids content as high as 50%, demonstrating its proficiency in processing viscous and particulate-laden materials.

- Broad Pressure and Flow Range: The pump offers a wide operational range with pressures reaching approximately 340 kgf/cm² (or 3.4 MPa) and flow rates up to 18600 cm³/min (or 18.6 L/min), accommodating a variety of applications and process demands.

- Isolation Functionality: The spiral sealing line effectively separates the suction and discharge cavities, akin to a valve, providing excellent isolation properties and preventing cross-contamination within the system. This feature further underscores the pump’s suitability for hygienic processes where sterility is of utmost importance.

Overall, SeFluid’s hygienic progressive cavity pump represents a superior engineering achievement, merging high-performance functionality with exceptional hygienic design to meet the rigorous demands of today’s industrial sectors requiring precise, efficient, and contaminant-free fluid transfer solutions.

Applications

Progressive cavity pumps (PCPs) have a wide range of applications due to their unique ability to handle viscous, shear-sensitive, and abrasive fluids with high efficiency and low pulsation. Here are some key areas where they are commonly used:

- Oil & Gas Industry:

- Artificial Lift: PCPs are often employed in oil wells as a method of artificial lift, particularly in heavy oil production or for wells that produce large amounts of sand and other solids.

- Produced Water Transfer: They can efficiently transfer produced water from the wellsite, which may contain high levels of solids and chemicals.

- Frac Fluid Transfer: In fracking operations, they can pump drilling muds and frac fluids at controlled flow rates.

- Wastewater Treatment:

- Sludge Handling: PCPs effectively move thick sludge and sewage without causing degradation due to their gentle pumping action.

- Food Processing:

- Fruit Pulp, Juices, and Sauces: They can handle high viscosity food products like tomato paste, jams, and fruit pulps without damaging product integrity.

- Dairy Products: Used in transferring and metering cheese curds, yogurt, and other dairy items that require gentle handling.

- Chemical Industry:

- Viscous Chemical Transfer: PCPs are used for dosing, metering, and transferring high-viscosity chemicals, pastes, and slurries.

- Pharmaceutical Industry:

- Drug Formulations: They’re suitable for handling delicate pharmaceutical formulations and suspensions that need careful processing.

- Agriculture:

- Manure Handling: For moving animal waste with high solid content, progressive cavity pumps provide a reliable solution.

- Mining:

- Mineral Processing: They can pump slurries containing fine particles, such as tailings, concentrates, or leaching solutions.

- Paper and Pulp Industry:

- Slurry Transport: PCPs are used to transport pulp stock and other viscous materials during the paper manufacturing process.

- Paints and Coatings:

- Material Transfer: These pumps are effective in transferring viscous paint and coating materials with precision.

- Biogas Production:

- Digestate Transfer: In biogas plants, PCPs are used to pump the digestate, a byproduct of anaerobic digestion, which is highly viscous and can contain fibrous material.

Generally, the versatility and robustness of progressive cavity pumps make them ideal for challenging fluid-handling tasks across various industries.

Request for Quotation

Talk To Us

We strongly recommend that you either click or scan the QR code below to talk directly with our sales engineers so that we can help you find the most suitable products for your application needs.

NEWS

CONTACT US

No 10, Jinhai Rd, Hefei, China 201400

Phone: +86 156 6910 1862

Fax: +86 551 5843 6163

moc.diulfesobfsctd-88671a@selas