Introduction of Mortar Spraying Machine

The mortar spraying machine is a kind of construction equipment used to spray mortar or cement on walls, ceilings, and floors. It is also called grout spraying pump, cement spraying machine, plaster spraying machine or mortar sprayer. The machine consists of a hopper that holds the mixture of mortar or cement along with water and an air compressor that helps in spraying the mixture onto surfaces using a hose and nozzle.

This kind of machine is commonly used for plastering buildings’ interior and exterior walls quickly, efficiently, and with less labor-intensive work compared to traditional methods. SeFluid’s mortar spraying machine series is the best choice for mixing, conveying and spraying all kinds of mortar, concrete, cement, plaster and grout in construction and engineering projects.

specification

Power

4-9 kw

Capacity

130-260 ㎡/h

Particle Size

6-7 mm

hopper

50-130 L

Principle of Mortar Spraying Machine

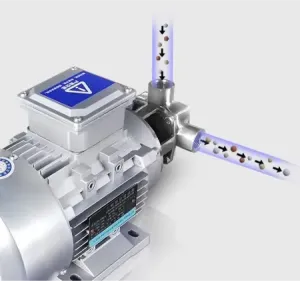

The basic components of a screw type mortar spraying machine include a hopper, a screw feeder, a spray gun, and an air compressor. The hopper is where the material is loaded, and it is designed to hold a large amount of material to reduce the need for frequent refills. A screw feeder is located at the bottom of the hopper, and it is responsible for transporting the material from the hopper to the spray gun. There is a spraying gun connected to the screw feeder and it is where the material is sprayed out. An air compressor is used to provide the necessary pressure to propel the material out of the spray gun and onto the surface being coated.

Screw feeder is the key component of a mortar spraying machine, and it works by using a rotating screw to transport the material from the hopper to the spray gun. The screw is typically made of a helical blade that is attached to a rotating shaft. As the screw rotates, it moves the material from the bottom of the hopper to the spray gun. The screw is designed to create a pressure gradient that forces the material through the spray gun at a controlled rate.

Speed of the screw feeder can be adjusted to control the rate at which the material is sprayed. This is important because different materials have different properties, such as viscosity and density, which can affect the spraying rate. By adjusting the speed of the screw feeder, the user can ensure that the material is sprayed at the optimal rate for the specific material being used.

The spray gun is designed to atomize the material as it is propelled out of the gun. This is done by using a combination of air pressure and a special nozzle that creates a fine mist of the material. The air compressor is used to provide the necessary pressure to propel the material out of the spray gun and onto the surface being coated. The pressure of the air can be adjusted to control the size of the droplets that are created, which can affect the quality of the coating.

In addition to the basic components, some screw type mortar spraying machines may also include additional features such as a remote control system, which allows the user to control the machine from a distance. This is particularly useful for large-scale construction projects where the user may need to move around the job site while the machine is in use.

Benefits of Mortar Spraying Machine

Mortar spraying machines have revolutionized the construction industry by offering numerous benefits over traditional mortar application methods. Some of the key advantages include:

Increased Efficiency

The machine’s automation drastically reduces the time and effort required to apply mortar, resulting in significant time savings and faster project completion. Additionally, the uniform application of mortar ensures better bonding between bricks and stones, improving the overall structural integrity.

Reduced Labor Costs

The use of a mortar spraying machine reduces the need for manual labor, which can be both costly and hard to find in today’s competitive construction market. This results in lower labor costs and a more cost-effective construction process.

Improved Quality

The even and consistent application of mortar by the machine ensures better bonding and a smoother finish, which translates to higher-quality structures with improved durability and longevity.

Reduced Material Waste

With precise control over the mortar application, the mortar spraying machine minimizes wastage of materials, leading to cost savings and a more environmentally friendly construction process.

Enhanced Safety

By eliminating the need for workers to manually handle heavy mortar loads and climb scaffolding, the use of a mortar spraying machine reduces the risk of accidents and injuries on construction sites.

Applications of Mortar Spraying Machine

Mortar spraying machines have a wide range of applications in the construction industry, including:

Masonry Construction

The primary application of the machine is in the construction of brick and stone walls, where they are used to apply the mortar that bonds the individual units together.

Plastering & Rendering

The machine can also be used to apply plaster or render to internal and external walls, providing a smooth, uniform finish that is both aesthetically pleasing and functional.

Grouting

In projects that require the filling of gaps or voids, such as in tunnel construction or soil stabilization, mortar spraying machines can be used to inject grout into the required areas.

Repair & Restoration

It can be used to apply repair mortar for the restoration of damaged or deteriorated structures, such as bridges, tunnels, and historic buildings.

Request for Quotation

news

contact

No 28, Fengxia Rd, Hefei, Anhui Province, China 201400

Phone: +86 156 6910 1862

Fax: +86 551 5843 6163

moc.diulfesobfsctd-15dd43@selas