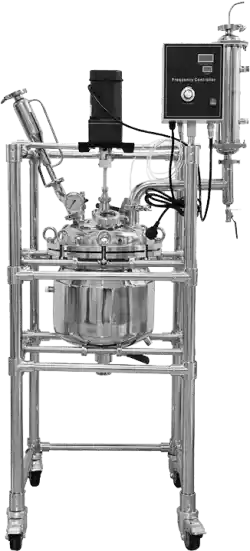

Introduction of Laboratory Reactor System

Laboratory Reactor System is a device used for chemical reactions, typically in a laboratory setting. SeFluid’s systems are made of 304 stainless steel, which is resistant to corrosion and high temperatures. The reactor is equipped with a constant pressure dropping funnel and a motor, which allows for precise control of reaction conditions. A pressure gauge can monitor pressure changes inside the reactor in real time, ensuring the safe operation of the experiment. The jacketed oil outlet and inlet allow for convenient addition or removal of the reaction medium.

Additionally, the reactor is equipped with a vacuum port and circulating water inlet and outlet, which enable vacuum operation and cooling water circulation, improving experimental efficiency. The universal wheel foot brake and solid feeding port design make operation more convenient. Overall, the laboratory reactor is a well-equipped and well-designed device suitable for various chemical reaction experiments.

Structure of The System

SeFluid’s Laboratory Reactor System is a full-featured, integrated system designed for a wide range of chemical reactions and consists of the following components:

- Controller: for setting and controlling the reaction conditions, such as temperature, pressure, stirring speed, etc.

- Vacuum port: for connecting external vacuum pump to realize vacuum operation during the reaction process, such as decompression distillation or removal of volatile components.

- Circulating water outlet: for discharging the circulating water in the reactor.

- Circulating water inlet: used to inject circulating water into the reactor to regulate the temperature of the reactor.

- Constant pressure drip funnel: used to precisely control the speed and amount of liquid added to the reaction system.

- Motor: to drive the stirrer to rotate, so that the reactants are fully mixed.

- Pressure gauge: displays the real-time pressure inside the reactor to help the operator monitor the reaction status.

- Reflux condenser: used to condense escaping vapors, prevent substance loss and promote reflux back into the kettle.

- Solid feed port: used to add solid reagents and sometimes liquids.

- Mezzanine outlet: for draining oil from the kettle jacket.

- Mezzanine oil inlet: for injecting oil into the jacket of the kettle to regulate the temperature of the kettle.

- Universal wheel with foot brake: the bottom of the reaction kettle is equipped with universal wheel with brake, which is easy to move and fix the position.

Specification

Power: 120w

Capacity: 1-5L

Material: SS304/SS316

RPM: 0-600

Advantages of SeFluid's Stainless Steel Laboratory Reactor System

Unveil the extraordinary advantages of SeFluid’s exceptional laboratory reactor system, a high-tech marvel meticulously crafted to withstand rigorous experimental conditions and meet the most demanding research needs.

- Firstly, at its core, SeFluid’s reactor is fabricated from top-grade 304 stainless steel. This material boasts an outstanding performance in withstanding high temperatures and pressures, ensuring it maintains stable physical properties under extreme conditions. Its high air-tight design guarantees no leakage during experiments while providing excellent corrosion and rust resistance. It resolutely stands up against strong acids, alkalis, and even aqua regia, offering 2-year maintenance for a worry-free experience amidst acidic and alkaline trials.

- Next, the driving force behind the SeFluid reactor is a German-engineered, original imported all-copper brushless frequency conversion motor. Boasting increased turbine copper core and high rotational speed, it delivers powerful suction and smooth, efficient operation. With low-friction bearings and a widened overall design, the motor achieves enhanced speed without compromising stability. Notably, this brushless technology eliminates sparks, significantly enhancing safety and stability, and comes backed by a lifetime free warranty service, ensuring a steadfast and durable power source for your experiments.

- Furthermore, SeFluid’s reactors are equipped with PTFE agitator blades that excel in resisting virtually any highly corrosive medium, including strong acids, strong bases, and a variety of organic solvents, thus ensuring uninterrupted chemical reactions during mixing processes.

- Additionally, SeFluid’s multi-functional reactor lid offers a unique customizability where opening sizes can be tailored according to individual client requirements, fully accommodating diverse experimental setups. Both the reactor body and lid are entirely cast in 304 stainless steel, featuring distinctive circular tenon-mortise sealing structures tightened with manual bolts, which greatly enhance impact resistance and durability, rendering the equipment robust and secure. Moreover, these components provide heightened resistance to oxidation and corrosion.

- Lastly, SeFluid’s laboratory reactor system incorporates a uniquely innovative digital display frequency converter, presenting clear, at-a-glance readings for operators to effortlessly monitor real-time data. Its user-friendly, intuitive controls simplify complex experimental procedures, making your scientific work more streamlined and efficient.

In summary, our laboratory reactor system, with its superior material selection, advanced manufacturing techniques, thoughtful design features, and robust safety measures, stands as the ideal choice for modern laboratory upgrades. It empowers researchers to navigate the frontiers of science with confidence and ease, achieving experimental objectives efficiently and effectively.

Applications

SeFluid’s stainless steel laboratory reactor system series are specially designed for the testing and trial production of many industries and have won the trust from hundreds of customers all over the world. The applications of our systems include:

- Chemical Synthesis

SeFluid’s laboratory reactor systems can be used to synthesize various chemicals, such as:

- Pharmaceutical intermediates: aspirin, vitamin C, etc.

- Fine chemicals: synthetic rubber, synthetic resin, etc.

- Flavors and fragrances: vanillin, menthol, etc.

- Dyes: indigo, active dyes, etc.

- Fertilizers: urea, compound fertilizers, etc.

For example, in the experiment of synthesizing aspirin, a laboratory reactor system can be used to esterify salicylic acid and acetic anhydride under the action of a catalyst to obtain aspirin.

- Materials Synthesis

Our laboratory reactor systems can be used to synthesize various materials, such as:

- Nanomaterials: nano gold, nano silver, etc.

- Advanced ceramics: alumina ceramics, silicon nitride ceramics, etc.

- Functional materials: superconducting materials, magnetic materials, etc.

For example, in the synthesis of nano gold, a laboratory reactor system can be used to reduce gold salt solution into nano gold under the action of a reducing agent.

- Biotechnology

Stainless steel laboratory reactor systems can be used for biotechnology applications, such as:

- Enzyme preparations: amylase, protease, etc.

- Fermentation: alcohol fermentation, lactic acid fermentation, etc.

- Cell culture: animal cell culture, plant cell culture, etc.

For example, in the production of enzyme preparations, a laboratory reactor system can be used to extract and purify the microbial fermentation liquid to obtain enzyme preparations.

- Food Processing

Stainless steel laboratory reactor systems can be used for food processing applications, such as:

- Food additives: sodium citrate, sodium benzoate, etc.

- Condiments: soy sauce, vinegar, etc.

Beverages: juice, soda, etc.

For example, in the production of soy sauce, a laboratory reactor system can be used to ferment soybeans, wheat and other raw materials to obtain soy sauce.

- Other Applications

Stainless steel laboratory reactor systems can also be used for other applications, such as:

- Environmental protection: wastewater treatment, waste gas treatment, etc.

- Energy and petrochemicals: petroleum refining, coal chemical industry, etc.

- Education and scientific research: university teaching, scientific research experiments, etc.

Generally, our laboratory reactor system is a versatile chemical equipment with important applications in various fields.

Request for Quotation

Talk to Us Now!

We strongly recommend that you either click or scan the QR code below to talk directly with our sales engineers so that we can help you find the most suitable products for your application needs.

NEWS

RELATED

CONTACT

No 10, Jinhai Rd, Hefei, China 201400

Phone: +86 156 6910 1862

Fax: +86 551 5843 6163

moc.diulfesobfsctd-8d95c0@selas