Introduction of Tubular Centrifuge

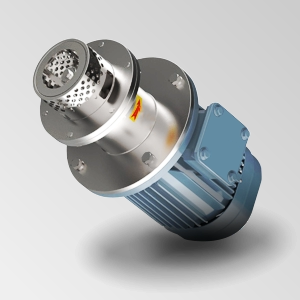

The tubular centrifuge is a kind of centrifuges that is designed to separate fluids based on their density. The centrifuge works by spinning a sample at high speeds, which causes heavier particles to move towards the outside of the tube and lighter particles to move towards the center. This creates a separation of the two fluids. The tubular design of the centrifuge allows for precise control over the separation of fluids. It is commonly used in pharmaceutical, biotech, and chemical industries for processing, purification, and clarifying of various fluids. The device is particularly useful for handling small volumes of sample and provides a quick and efficient separation of complex mixtures.

SeFluid’s tubular centrifuge series has numerous advantages, making them a top choice for many industries. With exceptional performance and reliable product quality, they have gained popularity among international users. Moreover, SeFluid’s tubular centrifuges are also known for their reliability. They are easy to operate and maintain, requiring minimal supervision and reducing the risk of downtime.

specification

Power

0.4-3.0 kw

Capacity

100-2500 L/h

Speed

10000-28000 rpm

Drum Diameter

45-142 mm

Material

SS304, SS316

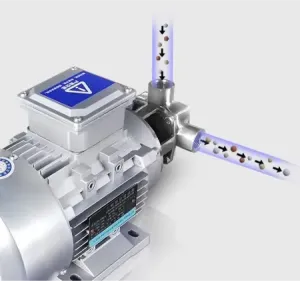

Principle of Tubular Centrifuge

Tubular centrifuges work on the principle of sedimentation. When a mixture of liquids and solids is introduced into the centrifuge, it is rotated at high speeds, generating centrifugal force. The centrifugal force acts on the particles in the mixture, causing them to separate based on their density. The heavier particles move towards the bottom of the tube, while the lighter particles move towards the top. This separation is facilitated by the high centrifugal force generated by the rotation of the rotor.

The machine consists of a cylindrical rotor, which rotates at high speeds, and a series of tubes that are attached to the rotor. The sample is introduced into the tubes, and as the rotor spins, the heavier particles in the sample move towards the bottom of the tube, while the lighter particles move towards the top. The separated components can then be collected and used for further analysis or processing.

Benefits of SeFluid's Tubular Centrifuge Series

The tubular centrifuge offers numerous advantages over other separation methods, making it the preferred choice for many applications. Some of the key benefits include:

High Efficiency

Its high rotational speed and large sedimentation area allow for rapid and efficient separation of components, even in complex mixtures.

Continuous Operation

Unlike batch centrifuges, it operates continuously, allowing for higher throughput and more consistent product quality.

Easy to Operate and Maintain

The machines have a simple design with few moving parts, which makes them easy to operate and maintain. They have a long service life and require minimal maintenance, reducing downtime and operational costs.

Compact Design

The machine’s compact design saves valuable floor space in production facilities and allows for easy integration into existing process lines.

Energy Efficiency

This centrifuge type consumes less energy compared to other separation methods, making them an environmentally friendly and cost-effective option.

Low Cost and Repeatedly

They are cost-effective and can be used repeatedly, making them a valuable investment for many industries. The tubes used in the centrifuge can be easily cleaned and reused, reducing the cost of consumables.

Applications of Tubular Centrifuge

Tubular centrifuges are used in a wide range of industries and applications due to their versatility, efficiency, and compact design. Some of the key applications include:

Pharmaceutical & Biotechnology Industry

It is extensively used in the production of vaccines, antibiotics, and other biopharmaceutical products. They help separate cells, cell debris, and other impurities from the product stream, ensuring high quality and purity.

Food & Beverage Industry

In the food and beverage industry, it is commonly used for the clarification of juices, wines, and other products. They help remove solids, such as fruit pulp and yeast, to produce a clear, high-quality product.

Chemical Industry

Tubular centrifuges are used in the chemical industry for the separation of liquid-liquid and liquid-solid mixtures, such as separating water from oil or removing solids from a liquid suspension.

Environmental Applications

The centrifuges are utilized for various environmental applications, such as wastewater treatment and sludge dewatering. They help separate solid contaminants from water, allowing for efficient waste disposal and water recycling.

Request for Quotation

NEWS

CONTACT

No 28, Fengxia Rd, Hefei, Anhui Province, China 201400

Phone: +86 156 6910 1862

Fax: +86 551 5843 6163

moc.diulfesobfsctd-849ef1@selas