What is ultrasonic mixer?

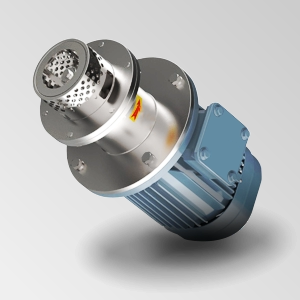

The ultrasonic mixer is a kind of device that uses ultrasonic cavitation effect to emulsify and mix materials. It also is called ultrasonic homogenizer or ultrasonic emulsifier.

Ultrasound is a sound wave with a vibration frequency of more than 20,000 Hz. It is a type of sound wave that can be fully utilized to serve human beings. As a physical means and tool, it can produce a series of conditions close to extremes in the medium of chemical reactions. The energy it produces can not only stimulate or promote the reaction between many substances, speed up the reaction speed, but even change the direction of some reactions, producing some unexpected effects and results.

As a professional mixer manufacturer, SeFluid has many years of experience in the field of ultrasonic mixing. Our ultrasonic mixers are widely used in various fields by users from all over the world.

specification

Power

500-3500 w

Resonant Frequency

20±1 KMz

Max. Work Pressure

5 Mpa

Material

Titanium alloy

How ultrasonic mixer works?

When a liquid is sonicated at high intensity, the sound waves propagating into the liquid medium create alternating cycles of high pressure (compression) and low pressure (ratherification) at a rate dependent on frequency. During low-pressure cycling, high-intensity ultrasonic waves create small vacuum bubbles or voids in the liquid. When the bubbles reach a volume where they can no longer absorb energy, they collapse violently and explode in a high-pressure cycle, a phenomenon known as cavitation.

During the explosion, a localized portion of the liquid will reach very high temperature (about 5,000K) and pressure (about 2,000atm). At the same time, the collapse of cavitation bubbles also leads to a liquid jet with a velocity of up to 280m/s, and the generated shear force mechanically stirs the liquid and fully mixes the reactants.

Benefits of Ultrasonic Mixer

The emulsion formed by emulsification with an ultrasonic mixer has a small average droplet size of 0.2-2um.

Ultrasonic mixers emulsify high-concentration emulsions. The concentration of the pure emulsion can exceed 30%, and the emulsifier can be as high as 70%.

The emulsion formed by ultrasonic mixing is more stable. An important feature of ultrasonic emulsification is that it can produce extremely stable emulsion without or with less emulsifier.

When emulsify toluene in water using an ultrasonic mixer, one type of emulsion can be formed under low sound intensity conditions, while another type of emulsion can be formed under high sound intensity conditions.

Emulsion type can be controllable. Using ultrasonic emulsification, under certain sound conditions, both O/W (oil in water) and W/O (water in oil) emulsions can be made, while mechanical emulsification is hard to achieve.

Features of SeFluid's Ultrasonic Mixer

1

Strong ultrasonic power density, better than low power density for liquid.

2

Can break macromolecular chains.

3

Can accelerated reaction to achieve shorter processing time.

4

Can increase the extraction rate and the utilization rate of raw materials.

5

Ultrasonic mixer can greatly reduce the energy consumption required for various mixing.

6

Multiple frequencies are available for SeFluid’s ultrasonic mixer series to fit various industries.

7

SeFluid’s ultrasonic mixer series are easy to install and low maintenance cost is required.

8

Suitable for high pressure, high temperature, toxic and explosive environments.

Applications of Ultrasonic Mixer

Processing Range

Destruction of cells and viruses; emulsification, mixing, dispersion, homogenization, catalysis, extraction, extraction, defoaming, descaling, cleaning, and accelerated reactions, etc.

Industrial Fields

Chemical industry, medicine, biology, petroleum, fuel, food, cosmetics, light industry, textile, metallurgy, papermaking, dyestuff, coating, lubricant, wastewater pollution prevention and other fields.

Request for Quotation

NEWS

CONTACT

No 10, Jinhai Rd, Hefei, China 201400

Phone: +86 156 6910 1862

Fax: +86 551 5843 6163

moc.diulfesobfsctd@selas