Introdução

Peristaltic pumps have found significant application in the mining industry, revolutionizing fluid handling processes and addressing the unique challenges faced in this sector. Here are some keyways peristaltic pumps have been used:

Construção em Alvenaria

Mining operations often involve the transportation of abrasive and high-density slurries containing solid particles. Peristaltic pumps excel in handling such slurries due to their gentle pumping action and the ability to handle high solid content. The rotating rollers compress the flexible tube, creating a squeezing action that propels the slurry through the tube without damaging the solids. This makes peristaltic pumps ideal for slurry transfer applications, such as moving tailings, thickened slurries, or mine dewatering.

Chemical Dosing and Metering

Accurate dosing of chemicals is critical in various mining processes, including flotation, pH adjustment, and flocculation. Peristaltic pumps offer precise and controlled flow rates, ensuring accurate chemical dosing and reducing wastage. Their positive displacement mechanism and reversible operation allow for precise metering, even at low flow rates. Peristaltic pumps can handle a wide range of chemicals used in mining, including acids, alkalis, flocculants, and reagents.

Wastewater Management and Treatment

Mining activities generate substantial volumes of wastewater that require effective management and treatment to minimize environmental impact. Peristaltic pumps are well-suited for transferring and treating wastewater in mining operations. Their self-priming capability allows them to handle varying fluid levels, making them suitable for applications such as sump pumping and drainage. The pumps’ gentle pumping action ensures minimal disturbance to settled solids, preventing re-suspension and facilitating efficient wastewater treatment processes.

Sampling and Analysis

Peristaltic pumps are widely used for sampling applications in mining. They enable precise and controlled extraction of fluid samples from different points in the process for analysis and testing purposes. The contamination-free operation of peristaltic pumps ensures that the integrity of the sample is maintained, avoiding cross-contamination or altering the sample composition. This makes peristaltic pumps invaluable in monitoring and analyzing critical parameters in mining operations, such as pH, metal content, or chemical composition.

Remote and Harsh Environment Operation

Mining operations often involve remote or inaccessible locations where reliable fluid handling is essential. Peristaltic pumps offer the advantage of remote operation and control, allowing them to be monitored and adjusted from a central control room. Additionally, peristaltic pumps are designed to withstand harsh environments commonly encountered in mining, including extreme temperatures, corrosive chemicals, and high vibration. Their robust construction, corrosion-resistant materials, and protection against ingress of solids or moisture make them suitable for use in rugged mining conditions.

Benefits of Peristaltic Pumps in Mining

Reduced Downtime

Peristaltic pumps have a simple design with minimal moving parts, resulting in reduced maintenance requirements and downtime. Tube replacement or cleaning can be performed quickly and easily, minimizing interruptions to mining operations.

Wear Resistance

The tubing used in peristaltic pumps is specifically chosen to withstand the abrasive nature of mining slurries and fluids. This enhances the pump’s durability, reduces wear and tear, and extends the pump’s lifespan.

Eficiência energética

Peristaltic pumps are known for their energy efficiency. They consume less power compared to other pump types, resulting in cost savings and reduced environmental impact.

Contamination-Free Operation

The fluid being pumped only comes into contact with the pump tubing in peristaltic pumps, ensuring contamination-free operation. This is crucial in mining applications where product purity is essential.

Versatilidade

Peristaltic pumps offer versatility in handling a wide range of fluids, including corrosive chemicals, viscous slurries, and fluids with varying solid contents. This versatility makes them adaptable to different mining processes and applications.

Precise Flow Control

Peristaltic pumps provide accurate and consistent flow control, ensuring precise dosing of chemicals or controlled transfer of fluids. This accuracy enhances process efficiency and reduces wastage.

Compatibility with Automation

Peristaltic pumps can be easily integrated into automated systems, allowing for seamless control and monitoring. They can be equipped with sensors and connected to control systems, enabling real-time data collection and process optimization.

Environmental Considerations

As bombas peristálticas oferecem benefícios ambientais nas operações de mineração. Seu manuseio eficiente de fluidos e dosagem precisa reduzem o consumo de produtos químicos e minimizam o impacto ambiental da descarga de águas residuais. Além disso, a sua eficiência energética contribui para os esforços globais de sustentabilidade.

Resumo

as bombas peristálticas tornaram-se ferramentas inestimáveis na indústria de mineração devido à sua capacidade de lidar com lamas abrasivas, capacidade de dosagem precisa e desempenho robusto em ambientes agressivos. Eles são usados para transferência de lama, desidratação, dosagem de produtos químicos, gerenciamento de águas residuais, amostragem e análise. Os benefícios das bombas peristálticas na mineração incluem tempo de inatividade reduzido, resistência ao desgaste, eficiência energética, operação livre de contaminação, versatilidade, controle preciso de fluxo, compatibilidade com automação e considerações ambientais. À medida que a indústria de mineração continua a evoluir, as bombas peristálticas provavelmente desempenharão um papel cada vez mais importante na melhoria dos processos de manuseio de fluidos e no aumento da eficiência operacional nas operações de mineração.

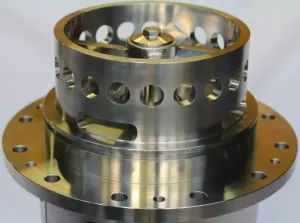

especificação

Pressão

0.8-1.6 Mpa

Capacidade

60-80000 l/h

Diâmetro da mangueira

10-125 mm

Material da mangueira

NR, EPDM, NBR, CSM

Solicitação de cotação

RELACIONADO

NOTÍCIAS

CONTATO

No 10, Jinhai Rd, Hefei, China 201400

Phone: +86 156 6910 1862

Fax: +86 551 5843 6163

poder.diulfesobfsctd-58d08a@selas