Mixer Pump

A mixer pump is an emulsification device installed on a pipe for continuous production or recycling of emulsified materials. It can disperse, shear and emulsified material in a short period of time. In the production process, a inline mixer can achieve continuous production. So, it can also be called continuous emulsification pump.

How does a mixer pump works?

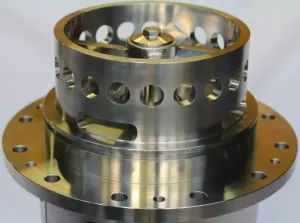

A mixer pump is composed of multi-stage stator and rotor, such as first, second and third stage, etc. Each stage is also layered. Different stage of the fixed rotor can make the material to achieve a different emulsification effect. The more layers the material passes through, the more delicate the role of dispersion and emulsification is. When the material enters the pump working cavity, it is necessary to reach the qualified material through high-speed shear of the layer-turned stator. A mixer pump can be configured with one or more sets of turners. Then the effect of emulsification is effectively improved.

There are two types of mixer pump: 1-stage and 3-stage. The pumps are made of 304/316 food-grade stainless steel and has outstanding corrosion and abrasion resistance. This makes the pump more durable. The processed material is not easy to contaminate hygienically clean. Mixer pumps are characterized by the production process. It is a combination of the following: dispersion, homogenization, mixing, crushing and conveying.

ilgili ürünler

SeFluid, Çin'in önde gelen sıvı işleme ekipmanı üreticisidir. Geçtiğimiz on yılda ürünlerimiz dünya çapında çok sayıda sıvı uygulamasında yaygın olarak kullanıldı. Daha fazla ayrıntı öğrenmek veya bize bir soru göndermek için lütfen aşağıdaki ilgili ürünlere tıklayın; satış mühendislerimiz sizinle en kısa sürede iletişime geçecektir.

Teklif Talebi

TEMAS ETMEK

No 10, Jinhai Rd, Hefei, Çin 201400

Telefon: +86 156 6910 1862

güç.diulfesobfsctd@selas