Mechanical mixing equipment consists of two major parts: mixing vessel and mixer. The mixing vessel includes the kettle body, outer jacket, internal components and various purposes such as open receiver; the mixer includes the agitator, stirring shaft, shaft seal, frame and transmission device and other components.

Mixing Vessel of Mixing Equipment

Mixing vessel is often called mixing tank (or stirring tank), when mixing equipment used as a reactor, is also known as mixing sensible reactor, sometimes referred to as the reaction sign.

The structure type of the gold body is usually vertical round business shape, its high diameter ratio is mainly based on the operation of the container loading liquid high diameter ratio and the size of the loading coefficient. The bottom shape has flat bottom, elliptical bottom, conical bottom, etc. Sometimes square kettle is also used. At the same time, according to the heat transfer requirements of the process, the vessel can be jacketed outside the body, and pass through steam, cooling and other heat-carrying media; when the heat transfer area is not enough, you can also set up coils inside the gold body, etc.

Mixer and Shaft of Mixing Equipment

Also known as an agitator or paddle, the mixer is the core component of the mixing equipment. According to the flow pattern produced by the agitator in the mixing tank, the agitator can basically be divided into two types: axial flow and radial flow. For example, propeller impeller, new type of wing impeller, etc. belong to axial flow agitator, while various real leaf and curved leaf turbine impellers belong to radial flow agitator.

The mixer shaft is usually inserted vertically into the kettle from the top center of the kettle, but sometimes it is also inserted laterally, at the bottom or laterally.

The power output of the motor in the mixing equipment is transmitted to the stirrer through the stirring shaft, so the stirring shaft must have sufficient strength. At the same time, the mixing shaft should be connected with the agitator and pass through the shaft seal device as well as bearings, couplings and other parts, so the mixing shaft should also have a reasonable structure, high machining accuracy and fitting tolerance.

Mixing Equipment Baffle of Mixing Equipment

In order to eliminate the liquid spinning phenomenon in the mixing tank, so that the mixed material can be up and down axial flow, the formation of the whole tank of uniform mixing, usually need to add a number of baffle plate in the mixing tank. The number of baffles is generally between 2 and 6, depending on the specific situation. After adding the baffle, the power consumption of mixing will increase obviously and increase with the number of baffles: but after meeting the condition of full baffle, then increase the number of baffles, the power consumption of mixing will not increase.

Usually, the width of baffle is about 1/12~~1/10 of the inner diameter of the tank, and the bottom baffle can be installed on the bottom of the tank The heat transfer coil in the stirring vessel can also replace the baffle in part or even in whole; when a vertical heat transfer tube is installed, the baffle can generally be removed.

Flow Guide tube of Mixing Equipment

The flow guide tube is a round simple with upper and lower openings, which is placed in the center of the mixing tank and plays the role of infusion in the mixing. Usually the upper end of the guide tube is lower than the static liquid level, and there are slots or holes in the tube body. When the liquid level falls in production, the material can still enter through the slot or hole.

Usually, the propulsion type agitator can be located in the flow guide tube or slightly below the lower end of the flow guide tube; the runner type or pulp type agitator is often placed at the lower end of the flow guide tube. When the agitator is placed under the flow guide tube, and the diameter of the simplified tube is larger, the diameter of the lower end of the tube should be reduced, so that the lower opening is smaller than the diameter of the agitator.

Shaft Seal (or magnetic drive) of Mixing Equipment

Shaft seal is an important part of the mixing equipment. The role of shaft seal is to ensure that the mixing equipment is under a certain positive pressure or vacuum to prevent the escape of the stirred material and the infiltration of impurities, so not all shaft seal types can be used in mixing equipment. In the mixing equipment, the most commonly used shaft seals are liquid seal, packing seal and mechanical seal.

When the mixing medium is highly toxic, flammable, explosive, or more expensive high-purity materials, or need to operate in a high vacuum state, the sealing requirements are very high, and the packing seal and mechanical seal can not meet, you can use the fully enclosed magnetic drive.

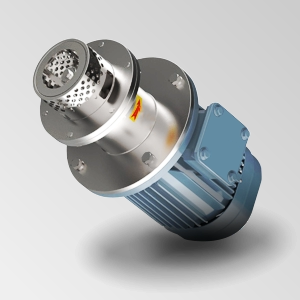

Magnetic drive device, also known as magnetic coupling, is one of the fully enclosed seals. It is the use of permanent magnets of different poles to absorb each other, the same pole after the principle, through the air gap and isolation membrane (sleeve) to transfer the mechanical movement into the confined space. Compared with the traditional packing seal and mechanical seal, the main advantage of magnetic transmission device is that it can achieve zero leakage, but the manufacturing cost is higher, and it is currently used more in medium and small mixing equipment.

Power Transmission of Mixing Equipment

The transmission device of mixing equipment includes motor, transmission, coupling, bearing and frame. Among them, the mixing drive mechanism usually adopts the combination of motor and transmission or the motor with frequency converter to make the mixer reach the required speed.

The role of the transmission is to ensure that the mixer shaft rotates at the required speed and that the mixer shaft receives the stored torque. In most of the mixing equipment, there is only one mixing shaft and the agitator rotates in one direction at a constant speed. However, there are some special mixing plants where two mixing shafts can be used in one mixing plant to obtain better mixing results, and the agitator can perform complex movements, such as reactive, reciprocating, planetary, etc.