Introduction of Magnetic Agitator

The magnetic agitator is a specialized mixer designed for production conditions with high sanitary requirements and a need for complete sealing. Unlike traditional mixers that rely on dynamic type seals, the magnetic mixer utilizes static seals and magnetic drive technology, effectively eliminating issues such as leakage and medium pollution caused by seal wear. As the biopharmaceutical industry continues to advance, mixers have become essential equipment in integrated systems.

Currently, most agitators employ single-end or double-end mechanical seals, which are dynamic type seals requiring lubrication and cooling. However, these traditional sealing technologies have inherent drawbacks such as material contact, temperature rise, wear, material shedding, susceptibility to pollution, and challenging maintenance. Consequently, mechanical seals are unsuitable for the biopharmaceutical industry, particularly in applications requiring high levels of air tightness.

SeFluid’s leak-free magnetic mixer series addresses these concerns by providing a specially designed mixer that ensures complete leak-free operation. It eliminates any possibility of leaks and is particularly well-suited for stirring in highly sealed conditions.

How the Magnetic Agitator Works

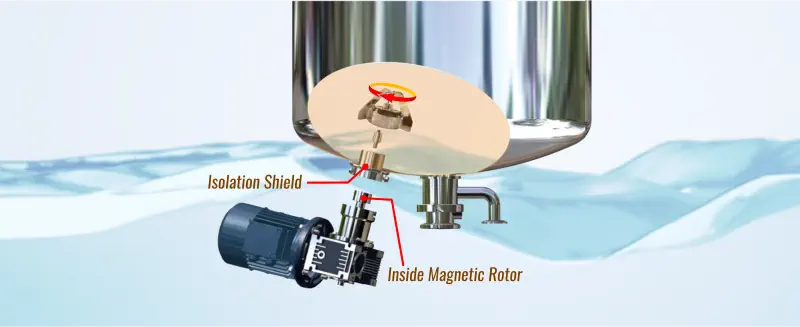

A magnetic agitator works on the principle of magnetic coupling, which enables it to mix fluids in a sealed or sanitary environment without any mechanical seals that could cause leaks or contamination. Here’s how it operates:

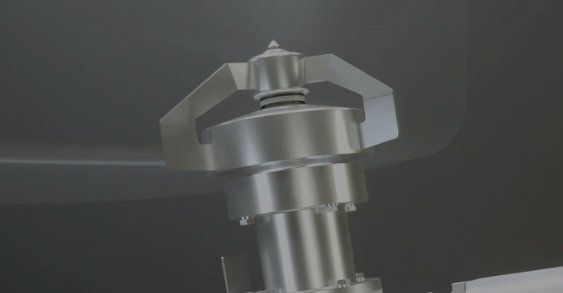

- Magnetic Drive System: The magnetic agitator consists of two main components: an internal rotor (impeller) and an external drive unit. The impeller is placed inside the mixing vessel where the process fluid is present. This impeller contains a strong permanent magnet.

- External Driver: The external driver, located outside the sealed container, also has a powerful magnet that aligns with the one in the impeller. When the external driver rotates, it creates a rotating magnetic field.

- Induction: As the magnetic field from the external driver changes, it induces a corresponding rotation in the impeller due to magnetic coupling. This causes the impeller to rotate within the sealed tank without any physical connection between the two magnets.

- Mixing Action: The rotation of the impeller then facilitates the mixing action within the process fluid, ensuring thorough blending while maintaining a completely sealed environment. There’s no risk of leakage because there are no shaft seals or penetrations through the vessel wall.

- Control and Adjustment: Speed control can be achieved by adjusting the external drive motor, allowing for precise and controlled mixing according to the specific requirements of the process.

This design not only eliminates the possibility of product leakage but also reduces maintenance needs as there are no wearing parts in contact with the process fluid, making magnetic mixers ideal for applications in industries like pharmaceuticals, biotechnology, and food processing where hygiene standards are stringent and contamination risks must be minimized.

Specification

Power: 0.4-18.5 kw

Capacity: 50-50000 L/batch

Speed: 50-960 rpm

Mounting: bottom, top

Advantages of Magnetic Agitators

The magnetic agitator offers several advantages that make it a preferred choice in various industries, especially in high sanitary conditions like the biopharmaceutical industry. These advantages include:

- Leak-free Operation: The magnetic agitator features a static seal, ensuring complete sealing and eliminating the risk of leaks. This is crucial in industries where product integrity and preventing cross-contamination are paramount.

- Sanitary and Aseptic Mixing: Magnetic agitators are ideal for sterile and high-sanitary applications as there’s no direct contact between the motor and the mixing vessel. This ensures that the process fluid remains uncontaminated, which is critical in pharmaceuticals, biotechnology, and food industries.

- Safety Improvements: By eliminating the risk of leakage from seals, magnetic agitators also reduce the risk of hazardous material exposure, chemical spills, and accidents.

- CIP/SIP Compatibility: Their design allows for easy cleaning-in-place (CIP) and sterilization-in-place (SIP), streamlining production processes and reducing downtime for cleaning and sanitization.

- Reduced Maintenance Requirements: With its static seal and absence of dynamic type seals requiring lubrication and cooling, the magnetic agitator reduces maintenance needs. This leads to cost savings and minimizes downtime for maintenance activities.

- Versatile Applications: Magnetic agitators can be used in a wide range of applications and industries, including biopharmaceuticals, food and beverage, cosmetics, and chemical processing. Their versatility makes them suitable for various mixing requirements.

Overall, the magnetic agitator’s leak-free operation, efficient mixing capabilities, elimination of pollution and contamination, reduced maintenance requirements, and versatility make it an advantageous choice for industries that prioritize high sanitary conditions and reliable mixing processes.

Installation Types

Magnetic agitators, also known as magnetic mixers, come in various installation types to accommodate different process requirements and vessel configurations. Here are some common installation types:

- Top-Mounted: This is the most common installation type where the magnetic drive unit is mounted on top of the mixing tank or reactor. The internal impeller is inserted into the vessel through a standard opening such as a flange or nozzle. Top-mounted designs allow for easy access to the motor and drive components.

- Bottom-Mounted: In this configuration, the magnetic drive system is installed beneath the tank. It’s particularly useful when space above the tank is limited or when working with high-viscosity materials that require bottom entry agitation for better mixing performance.

- Side-Entry: For vessels with limited openings on the top, side-entry magnetic agitators can be used. The magnetic drive assembly is fixed to the side of the tank, and the impeller enters the liquid from the side wall.

- Inline or Tube-Type: Designed for pipeline or closed-loop systems, inline magnetic agitators integrate directly into the fluid flow path, providing continuous mixing without requiring an additional mixing tank.

- Flange-Mounted: The magnetic drive is directly connected to the vessel via a flange, offering a secure seal and easy installation/removal.

- Portable or Clamp-On: These are compact units that can be clamped onto the side or top of smaller containers or vessels, making them highly versatile and adaptable for various batch processes.

- Custom Configurations: Magnetic agitators can also be customized to fit unique applications, including angled or offset impellers, multiple impellers for multi-zone mixing, and more.

Each installation type is chosen based on factors like the geometry of the vessel, the properties of the material being mixed, process conditions, and any space constraints in the production environment.

Applications of Magnetic Agitators

- Biopharmaceuticals: In the pharmaceutical and biotechnology sectors, magnetic agitators are used for mixing sensitive biological materials like cell cultures, vaccines, APIs, and other sterile formulations in fermentation vessels or bioreactors.

- Food & Beverage: They are ideal for food processing where strict hygienic standards must be maintained, such as in blending dairy products, sauces, jams, and beverages. The absence of mechanical seals prevents any chance of product contamination.

- Chemical Industry: For mixing chemicals that can be hazardous, corrosive, or highly viscous, magnetic mixers provide a safe solution without risking leaks or spills. They’re also suitable for reactions under pressure or vacuum conditions.

- Cosmetics and Personal Care: In this industry, magnetic agitators help create homogeneous emulsions, suspensions, and lotions while maintaining high sanitary standards.

- Semiconductor and Electronics: Magnetic stirrers are commonly used in cleanroom environments for mixing chemical baths and slurries with zero risk of particulate contamination.

- Water Treatment: They can be employed in water treatment plants for mixing chemicals during purification processes, ensuring even distribution and avoiding environmental pollution from seal leakage.

- Laboratory Applications: Smaller-scale magnetic stirrers are widely used in laboratories for research and development, sample preparation, and testing procedures requiring controlled and precise mixing.

- Nuclear Industry: Given their reliability and safety features, magnetic agitators are used in nuclear waste treatment and fuel reprocessing plants.

In summary, magnetic agitators play a pivotal role in various industries that require efficient, controlled, and contamination-free mixing operations.

Features of SeFluid's Magnetic Agitators

SeFluid’s magnetic agitators are designed with several key features that make them efficient, versatile, and easy to maintain. These features include:

Dry run Allowance: SeFluid’s magnetic agitators can operate without liquid, reducing wear and tear on the equipment.

Low Maintenance cost: The agitators have no bearings, which means they require less maintenance than traditional mixing systems.

Simple Structure: The agitators have a simple design that makes them easy to dismantle and clean, ensuring there are no dead spaces where contaminants can accumulate.

Excellent Mixing Quality: SeFluid’s magnetic agitators offer customizable mixing blades for different mediums, ensuring optimal mixing results.

Ideal for Closed Spaces: The agitators are ideal for use in absolutely closed spaces, making them cleaner and more airtight.

Suitable for Various Tank Types: SeFluid’s magnetic agitators can be used with various tank types, including those with heating and stirring capabilities.

Compact Structure: The agitators have a compact structure that is frictionless and leak-free, making them capable of online cleaning and sterilizing.

No Leakage: SeFluid’s magnetic agitators replace dynamic mechanical seals with welded isolation sleeve static seals, ensuring complete leak prevention.

Overall, SeFluid’s magnetic agitators offer a range of benefits that make them an excellent choice for a variety of applications. Their innovative design and advanced features ensure efficient mixing, low maintenance costs, and reliable performance.

Request for Quotation

Talk to Us Now!

We strongly recommend that you either click or scan the QR code below to talk directly with our sales engineers so that we can help you find the most suitable products for your application needs.

NEWS

RELATED

CONTACT

No 28, Fengxia Rd, Hefei, Anhui Province, China 201400

Phone: +86 156 6910 1862

Fax: +86 551 5843 6163

moc.diulfesobfsctd-1859a2@selas