Definition of Mechanical Defoamer

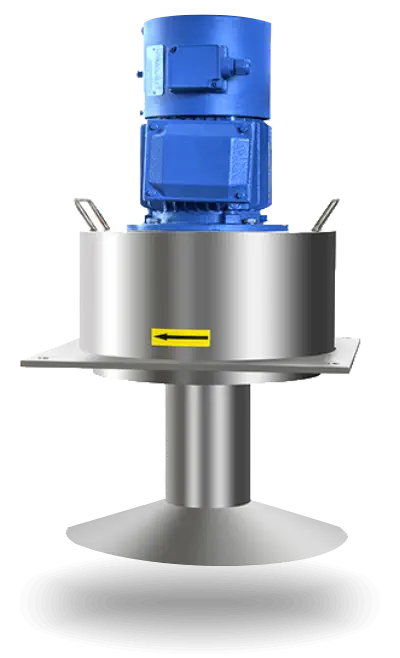

The mechanical defoamer, also called foam breaker, is a kind of industrial defoaming equipment, also known as foam breaker or defoaming machine. Its function is to use centrifugal force to break the foam produced in the production process and separate the gas and liquid.

Defoaming is to take certain measures to break the formed foam or reduce the thickness of the foam layer. The rupture of the bubble is to destroy the film that forms the bubble. To recycle foam fluid, the premise is that there must be a feasible method of defoaming. There are many commonly used defoaming methods, which can be divided into physical defoaming method, mechanical defoaming method, chemical defoaming method and natural defoaming method according to the principle. Compressing bubbles or applying impact force, using rapid changes in pressure, such as shear force, compression force, and impact force, can rupture the bubble film to achieve the purpose of defoaming.

This SeFluid’s mechanical defoamer and foam breaker series takes the mechanical force generated by the impeller to achieve defoaming. It defoams quickly and without adding chemical defoamer and any other substances, which can ensure the purity of the product. It is highly efficient and energy-saving, and suitable for filtration, mixing, separation, fermentation, extraction and other process steps. Therefore, it is a good tool for foam inhibition, and defoaming in industry.

specification

Power

0.75-37 kw

Capacity

5-500 m³/h

Mounting

Tank top, beam, mobile

Material

SS304, SS316

Working Principle of Mechanical Defoamer

During the working process, the high-speed rotating module provides strong shearing force and tears up air bubbles. Then, the liquid released by the bubble is immediately thrown against the wall by centrifugal force, and compressed into a liquid stream to return to the liquid. At the same time, it can reduce the loss of escaped liquid.

The Reason to Take SeFluid's Mechanical Defoamer Series

Compared with traditional defoamers, our mechanical defoamer solves the problems of manual timing, potential media pollution, and long-term purchase costs. Therefore, it has a wide range of applications, suitable for cleaning, stirring, separation, fermentation, extraction, drying and other process links. Moreover, our machines are customizable to meet special application needs.

The Hazards of No Using a Foam Breaker

Impact on Product Quality

Some production processes produce large amounts of foam, such as dyeing and printing in the textile industry. The retention of air bubbles leads to spots and blemishes on the finished cloth. In pulp production, the foam of pulp can cause hazards to environmental hygiene and workers’ health. Also, the finished paper will have many holes, causing a serious decline in product quality.

Greatly Limit Production Capacity

In various biological fermentations (beer production, alcohol manufacturing, production of major antibiotics on pharmaceuticals), various fermenters, reactors, cooking tanks and other equipment are used. In order to prevent the appearance of foam leading to diffusion losses, the feeding factor has to be greatly reduced, sometimes to less than 30%.

Prolongs the Reaction Time

Since the chemical reaction products include gases and liquids, foam causes gas stagnation and prolongs the reaction time. This unnecessarily consumes more power.

Causes Waste of Raw Materials

Useful or valuable raw materials due to foam and overflow losses, resulting in waste. Such as paper mills, sugar mills in the process of filling, textile mills weaving process of oiling process, often caused by foam and overflow.

Bad for Accurate Measurement

In industrial production, foam can interfere with the measurement of liquid level meters and cause measurement errors. The foam in the liquid can make the liquid density fluctuate greatly. In addition, foam can also cause the reactor absorption tower, distillation tower liquid level false high, resulting in operational errors, or even accidents.

Request for Quotation

NEWS

contact

No 28, Fengxia Rd, Hefei, Anhui Province, China 201400

Phone: +86 156 6910 1862

Fax: +86 551 5843 6163

moc.diulfesobfsctd-43a12e@selas