A sanitary centrifugal pump is a specialized type of centrifugal pump designed for use in hygienic or sanitary applications where high levels of cleanliness and minimal risk of contamination are critical. These pumps are typically used in the food, beverage, pharmaceutical, and biotechnology industries to handle products that require strict hygiene standards during processing. SeFluid’s sanitary centrifugal pumps adopt smooth, rigid structure and thick wall design. Meanwhile, the pumps have great improved wear resistance ability and extended service life.

specification

Power

0.37-7.5 kw

Capacity

1-30 m³/h

Flow head

8-36 m

Material

SS304, SS316

How sanitary centrifugal pump works

A sanitary centrifugal pump works on the principle of centrifugal force to transfer fluids while maintaining sanitary conditions. Here’s a general overview of how it operates:

Pump Assembly

A typical sanitary centrifugal pump consists of several components, including an impeller, casing, shaft, mechanical seal, and motor. The pump is designed to be hygienic, with smooth surfaces and minimal dead spaces to prevent contamination.

Inlet and Outlet

The pump has an inlet where the fluid enters and an outlet where the fluid is discharged. The inlet is usually connected to a pipe or a tank containing the fluid to be pumped.

Impeller

The impeller is a rotating component inside the pump. It is typically made of stainless steel and is designed with curved vanes. When the pump is operating, the impeller spins rapidly, creating centrifugal force.

Centrifugal Force

As the impeller rotates, the centrifugal force generated causes the fluid to move outward from the center of the impeller. This force pushes the fluid towards the periphery of the impeller.

Casing

The casing is the stationary part of the pump surrounding the impeller. It is designed to guide the fluid from the impeller’s outer edge to the pump’s outlet. The casing’s shape and design help to maintain a constant flow path and direct the fluid in the desired direction.

Pressure Difference

As the fluid moves from the impeller’s center to the outer edge, the pressure increases due to the centrifugal force acting on it. This pressure difference allows the fluid to be pushed out through the pump’s outlet.

Mechanical Seal

The pump is equipped with a mechanical seal to prevent leakage of the fluid. It ensures that the fluid does not enter the pump’s motor or escape into the environment.

Motor

The pump is driven by an electric motor that provides the rotational energy required to spin the impeller. The motor is usually sealed and designed to withstand the sanitary requirements of the application.

Flow Control

The flow rate of the pump can be controlled by adjusting the motor speed or using additional flow control devices such as valves or throttling devices.

Clean-in-Place (CIP) and Sterilize-in-Place (SIP)

Sanitary centrifugal pumps are designed for easy cleaning and sterilization. They may have self-draining capabilities, polished surfaces, and quick disassembly features to facilitate thorough cleaning and sterilization cycles.

Structure of sanitary centrifugal pump

The structure of a sanitary centrifugal pump consists of various components that work together to transfer fluids while maintaining sanitary conditions. Here is a breakdown of the key components:

Casing/Housing

The casing, also known as the volute, is the outer shell of the pump. It encloses and supports the impeller and other internal components. The casing is typically made of stainless steel or other food-grade materials and is designed to be smooth and free of crevices to prevent product buildup and facilitate easy cleaning.

Impeller

The impeller is a rotating component located inside the casing. It consists of curved vanes or blades that impart centrifugal force to the fluid as it rotates. The impeller is driven by a motor and is designed to efficiently move fluids through the pump.

Shaft

The shaft is a cylindrical rod that connects the impeller to the motor. It transmits the rotational motion from the motor to the impeller, causing it to spin. The shaft is typically made of stainless steel or another corrosion-resistant material.

Mechanical Seal

The mechanical seal is a crucial component that prevents leakage of the fluid from the pump. It is located at the shaft where it exits the casing. The mechanical seal consists of stationary and rotating parts that create a tight seal to prevent fluid from escaping or contaminants from entering the pump.

Inlet and Outlet

The pump has an inlet through which the fluid enters the casing and an outlet through which the fluid is discharged. The inlet is typically connected to a pipe or a tank containing the fluid to be pumped, while the outlet directs the fluid to the desired location.

Bearings

Bearings support the rotating shaft within the pump. They ensure smooth rotation and reduce friction between the shaft and the casing. Bearings are typically located at both ends of the shaft and are designed to withstand the sanitary requirements of the application.

Motor

The motor provides the rotational energy required to drive the impeller. It is typically an electric motor that is sealed and designed to meet the sanitary requirements of the application. The motor is connected to the shaft and provides the power necessary for the pump’s operation.

Connections and Fittings

Sanitary centrifugal pumps have various connections and fittings, such as sanitary clamps, tri-clamp connections, or flanges, that allow for easy installation and disassembly. These connections ensure proper alignment and secure attachment of the pump to the process piping system.

Covers / Endplates

Access covers or endplates are designed to allow for easy access to internal components for maintenance, cleaning, and inspection.

Material of Sanitary Centrifugal Pump

The materials used in sanitary centrifugal pumps are carefully selected to be compatible with the fluids being handled and to meet the sanitary requirements. The specific material choices may vary depending on the application and industry, but some commonly used materials include:

Stainless Steel

Stainless steel is a popular choice for sanitary centrifugal pumps due to its corrosion resistance, durability, and ease of cleaning. Different grades of stainless steel, such as 316L or 304, may be used depending on the specific application.

Food-Grade Plastics

Certain food-grade plastics, such as high-density polyethylene (HDPE) or polytetrafluoroethylene (PTFE), may be used in the construction of sanitary centrifugal pumps. These materials are non-reactive, resistant to chemicals, and offer good durability.

PTFE (Teflon)

Polyethylene tetrafluoroethylene (PTFE), commonly known as Teflon, is highly resistant to chemicals and provides excellent non-stick properties. It is often used for components such as seals, gaskets, or linings in sanitary centrifugal pumps.

Rubber and Elastomers

Certain types of rubber and elastomers, such as EPDM (ethylene propylene diene monomer), Viton (fluoroelastomer), or silicone, may be used for sealing elements or other parts requiring flexibility and resistance to temperature and chemicals.

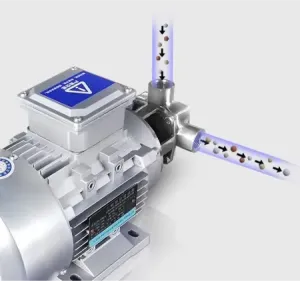

Unique Design of SeFluid's Sanitary Centrifugal Pump

The impeller and shaft sleeve of SeFluid’s sanitary centrifugal pump series are precision cast as a single unit. They are directly mounted on the motor output shaft, offering advantages such as high strength, simple installation, and excellent precision. This design ensures optimal concentricity, effectively solving vibration issues while enhancing the pump’s overall strength. The precision casting of the impeller and shaft sleeve effectively addresses wear problems between the impeller and the hub. Additionally, the shaft sleeve is designed to extend into the rear end of the impeller, improving the pump’s inlet characteristics and preventing cavitation erosion.

The impeller is of an open type, allowing for easy cleaning. Both the pump body and impeller are cast as a single piece, ensuring a smooth and well-treated surface. Furthermore, the shaft seal is designed with an open structure, enabling convenient observation of the pump. Even a minor leakage at the shaft seal can be easily detected, allowing the user to take prompt action before the fluid overflows into the motor. This feature guarantees the motor’s longevity and uninterrupted operation.

Advantages of Centrifugal Hygienic Pump

Sanitary centrifugal pumps offer several advantages in industries where the hygienic handling of fluids is crucial. Here are some key advantages of sanitary centrifugal pumps:

Hygienic and Sanitary

Sanitary centrifugal pumps are specifically designed to meet strict sanitary standards and regulations. They feature smooth, crevice-free surfaces without any dead zones or pockets where bacteria or contaminants can accumulate. This design minimizes the risk of product contamination, ensuring the integrity and safety of the fluid being transferred.

Corrosion Resistant

Many sanitary centrifugal pumps are constructed from corrosion-resistant materials such as stainless steel or food-grade plastics. This resistance to corrosion ensures the longevity and durability of the pump, even when handling aggressive or corrosive fluids. It also helps maintain the hygienic integrity of the system over time.

Easy to Clean and Sterilize

Sanitary centrifugal pumps are designed for easy and effective cleaning. The smooth surfaces and absence of crevices allow for thorough cleaning and sterilization procedures, minimizing the risk of cross-contamination between batches or products. This is particularly important in industries such as food, beverage, and pharmaceuticals, where maintaining a high level of cleanliness is essential.

Reduced Maintenance

Sanitary centrifugal pumps are designed for easy maintenance and servicing. Their construction allows for quick disassembly and reassembly, facilitating inspections, cleaning, and repairs. Additionally, the use of high-quality materials and robust construction reduces the frequency of maintenance tasks and extends the lifespan of the pump.

Efficiency and Performance

Centrifugal pumps are known for their high efficiency and reliable performance. They can generate high flow rates and provide a consistent pressure, ensuring efficient transfer of fluids. This is crucial in industries where precise control and accurate dosing of fluids are required.

Applications of Sanitary Centrifugal Pump

Sanitary centrifugal pumps find applications in various industries where the hygienic transfer of fluids is critical. Some common applications of sanitary centrifugal pumps include:

Food and Beverage Industry

Sanitary centrifugal pumps are extensively used in the food and beverage industry for handling products like milk, juices, beer, wine, sauces, syrups, and other liquid foodstuffs. They are employed in processes such as product transfer, filtration, mixing, filling, and CIP (clean-in-place) systems.

Pharmaceutical Industry

In the pharmaceutical industry, sanitary centrifugal pumps are used for transferring and handling pharmaceutical liquids, including active ingredients, suspensions, emulsions, and sterile solutions. These pumps maintain the purity and integrity of the products during processing and ensure compliance with stringent regulatory requirements.

Biotechnology and Life Sciences

Sanitary centrifugal pumps play a crucial role in biotechnology and life sciences applications. They are used for transferring and handling biopharmaceuticals, vaccines, cell cultures, enzymes, media, and other sensitive fluids. These pumps are designed to maintain the sterility and viability of biological materials.

Cosmetics and Personal Care Industry

Sanitary centrifugal pumps are employed in the cosmetics and personal care industry for handling products like lotions, creams, shampoos, gels, and other liquid cosmetics. They ensure the hygienic transfer of these products during manufacturing and packaging processes.

Dairy Industry

Sanitary centrifugal pumps are widely used in the dairy industry for handling milk, cream, yogurt, butter, and other dairy products. They are employed in processes such as milk transfer, pasteurization, homogenization, and cream separation.

Brewery and Distillery Industry

In the brewery and distillery industry, sanitary centrifugal pumps are used for transferring wort, beer, spirits, and other alcoholic beverages. They are utilized in various stages of production, including mash transfer, fermentation, filtration, and bottling.

Chemical and Industrial Processes

Sanitary centrifugal pumps are also used in chemical and industrial processes where the handling of sanitary fluids is necessary. They are employed for transferring various chemicals, solvents, reagents, and other sensitive liquids.

Request for Quotation

news

contact

No 10, Jinhai Rd, Hefei, China 201400

Phone: +86 156 6910 1862

Fax: +86 551 5843 6163

moc.diulfesobfsctd-5be944@selas